Akroh Industries in the north of the Netherlands produces a wide range of plastic products for various industries, including the agricultural, automotive and healthcare sectors. Wittmann Macropower injection moulding machines are among the company's preferred machine types and play a key role in its growth strategy. The company recently installed a new "Macropower 2000" from Wittmann, which, with a clamping force of 2,000 tonnes, is by far the largest injection moulding machine ever put into operation at Akroh. This investment marks a new chapter for the family-run company. Following the massive expansion of the machine park, the contract injection moulding division, which currently accounts for around 20 percent of turnover, is now to be further expanded. We are continuously stepping up the product portfolio for our customers”, states Ar-end-Jan Horst, owner and CEO of Akroh Industries.

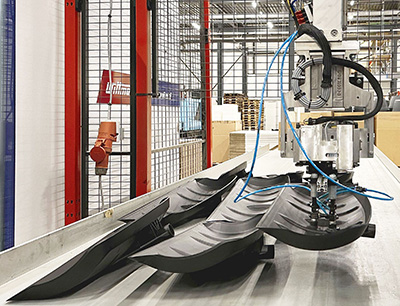

Since its foundation in 1956, the product programme has changed and diversified several times. Today, the company's own products are focussed on agricultural applications. Akroh has become particularly well known in Europe with equipment for the livestock and dairy industries as well as tractor components. The company now supplies more than 7,000 different products and product variants to 60 countries worldwide via the agricultural trade. More than 600 injection moulds are in use, including for the production of the large black shovel blades, which roll off the production line on a "Macropower 850" injection moulding machine. Mounted on a wooden handle and fitted with a handle also injection-moulded from plastic, they are later marketed as feed shovels. The large components with a shot weight of 1,000 grams are produced in a single-cavity mould with a cycle time of 30 seconds. They are made of impact-resistant polypropylene, as they have to withstand a lot in the harsh conditions of everyday life in the barn and in the field. Between summer and winter, ambient temperatures can fluctuate from minus ten to plus 40 degrees Celsius without the stability of the buckets suffering. “With the Macropower we can rely on producing consistent high quality”, Arend-Jan Horst emphasizes, leading us to another Macropower machine, which molds large plant containers to a customer’s order. “Here, the requirements are even more stringent”, he explains. “The wall thickness is no more than 1.5 millimetre, yet we still achieve very high dimensional accuracy.”

This was not the case with the injection moulding machine from a Chinese manufacturer that Akroh purchased a few years ago for testing purposes. The sensor system of the Chinese machine quickly reached its limits, especially with thin-walled components that require high injection pressures. Another advantage of the Macropower in direct comparison with other machines is its small footprint. Due to the two-platen technology, the design of the Macropower is significantly shorter. The space requirement of production cells is generally a major issue. Akroh also pays attention to a compact layout when it comes to automation. A conscious decision was made to equip the new 2000 tonne machine with a linear robot. In contrast to a six-axis robot, which would take up additional floor space next to the machine, the Wittmann "WX173" linear robot is mounted directly on the machine above the clamping unit. To maximise flexibility when removing parts, Wittmann integrated two additional servo rotation axes for its customer. Depending on the mould, the servo C-axis can be used to switch flexibly between removal on the moving and fixed mould mounting platen.

The plasticising units in the Wittmann machines make a further contribution to the consistently high quality of the injection moulded parts. “All of our most recently delivered machines are equipped with MeltPro barrier screws, and we have now also retrofitted the existing machines”, reports Michel van der Motten, Managing Director of Wittmann Battenfeld Benelux NV. By this move, Akroh has prepared itself well for the future, since the proportion of regrind in the materials being processed is rising. When using a machine with a standard 3-zone screw to process materials with a high proportion of regrind, Akroh had to lengthen the plasticizing time in order to achieve sufficiently high melt homogeneity. “This means that for a number of products we would no longer have been cost-efficient”, Horst explains.

In addition, intelligent assistance systems from Wittmann's Hiq product range support the processing of recyclate. The Hiq Flow software determines the viscosity of the plastic melt during the injection phase of each cycle. If it deviates from the specified target value, the machine automatically compensates the injection volume in the same shot. The result: 100 percent good parts. With recycled plastics in particular, the MFI can fluctuate greatly from batch to batch. “With our Wittmann machines, we can still process high percentages of recycled material streak-free”, says Horst. “Since our introduction of Meltpro screws and Hiq Flow, we are not getting any more production-related scrap.” Some plant containers are already being produced entirely from recycled materials. For making the feeding shovels, ten per cent regrind are currently blended in. This regrind is entirely derived in-house from sprue and start-up scrap. “Keeping production scrap in the cycle is now an essential strategy for us to remain competitive with our prices”, Arend-Jan Horst emphasizes. “For the agricultural products, we have strong competitors in China, India and Pakistan. Here, the unit costs are invariably an important issue.”

“Our customers buy from us, because we deliver excellent quality, respond flexibly to customers’ wishes and are nevertheless not more expensive than the Asians”, the manager explains. “The price we are paying for this is a continuous flow of process optimization.” Consistently high reliability and stability of the machines are not enough. The availability and flexibility of the production systems are also closely examined by the Akroh management for every investment decision. “When we receive an order today, we can deliver it tomorrow”, this is how Arend-Jan Horst describes the extreme case, which actually happens quite often. Molds are changed twice or three times per day, and this must be done quickly to keep the machines’ uptime on a top level. The long-stroke system for releasing the tie-bars supports easy installation of large molds from one side, and what is more, the progressing digitalization of the production processes is already showing a positive effect here as well. “The machine recognizes the mold by reading out the mold data set and then automatically sets the correct parameters”, explains Horst. “Digitalization already offers many opportunities today for working even more efficiently. We intend to exploit these opportunities even more effectively in future”.

Transparency is a basic prerequisite for continuously optimising processes. In terms of energy efficiency, the Akroh team is currently launching a corresponding project. “We have set ourselves the task of measuring more. We look at all sources of energy consumption, not only those of the machines. Maybe it is possible after all to turn the temperature of the cooling water up by two degrees in one process or another. The energy prices have risen so sharply in the course of last year that even changes seemingly small at the first glance have a large effect. The important point for me is that we can continue production here in our homeland in spite of the high labor and energy costs - to this end we exploit all opportunities open to us.” As CEO of a family-owned company, Arend-Jan Horst thinks ahead on a long-term basis. “I was eleven years old when my grandpa bought his first injection molding machine”, he remembers. “That was a Battenfeld machine, and I learned injection molding on it.” Strong ties between Akroh and the Wittmann Group, of which Battenfeld today is a part, have been in existence ever since. “The excellent contacts are important to me”, Horst emphasizes. “Wittmann is a family-owned company like us, and family-owned companies work in a different way. People there talk openly with each other, which also makes it possible to plan the future together.”