Transparency is an essential part of Bell's corporate philosophy. This does not primarily refer to transparent plastic materials in production. Rather, Bell is committed to transparent communication with end users. This is because the Polish cosmetics manufacturer is focused on sustainability. Only equipment and systems that are very energy-efficient, such as Wittmann injection molding machines, robots, and dryers, are used in injection molding production. The machine park currently consists of 48 injection molding machines, all from the Wittmann Group and equipped with Wittmann linear robots. Expansion is planned for the coming months, as demand for Bell cosmetic products is growing rapidly.

Output more than doubled with the same energy consumption

It all began 35 years ago with the production of lipsticks. Today, Bell covers the entire range of decorative cosmetics and supplies its products to over 60 countries around the world. All primary packaging for makeup, eye shadow, and mascara is manufactured in-house with a strong focus on sustainability. Servo-hydraulic Smartpower and fully electric Ecopower injection molding machines dominate the picture. The number one decision criterion when investing in new injection molding technology is energy efficiency. “With every new machine, the energy efficiency increases even further,” Production Manager Waldemar Gula reports. “At the beginning of our efficiency boosting program, we were producing nine million parts per month. Now this has gone up to twenty million, but still our energy consumption in the injection molding shop has remained the same.”

Injection molding machines recover braking energy from drives

The production manager attributes this success to the consistent use of injection molding machines from the Wittmann Group. The machines in the Ecopower series are equipped with highly dynamic servo motors to drive the main movements. With the help of Kers, the braking energy of the drives is recovered and used within the machine, for example to supply power to the control system or to heat the cylinders. “Kers stands for Kinetic Energy Recovery System,” explains Bogdan Zabrzewski, Managing Director of the Wittmann branch in Poland. “With Kers, a further reduction of energy consumption by up to five percent is possible.”

The servo-hydraulic Smartpower machines from the Wittmann Group also work with Kers. This series combines responsive servo motors with powerful constant pumps. For injection molding, this means maximum dynamics, speed, and precision of machine movements with minimal energy consumption.

Customized dryer solution for glycol-modified PET

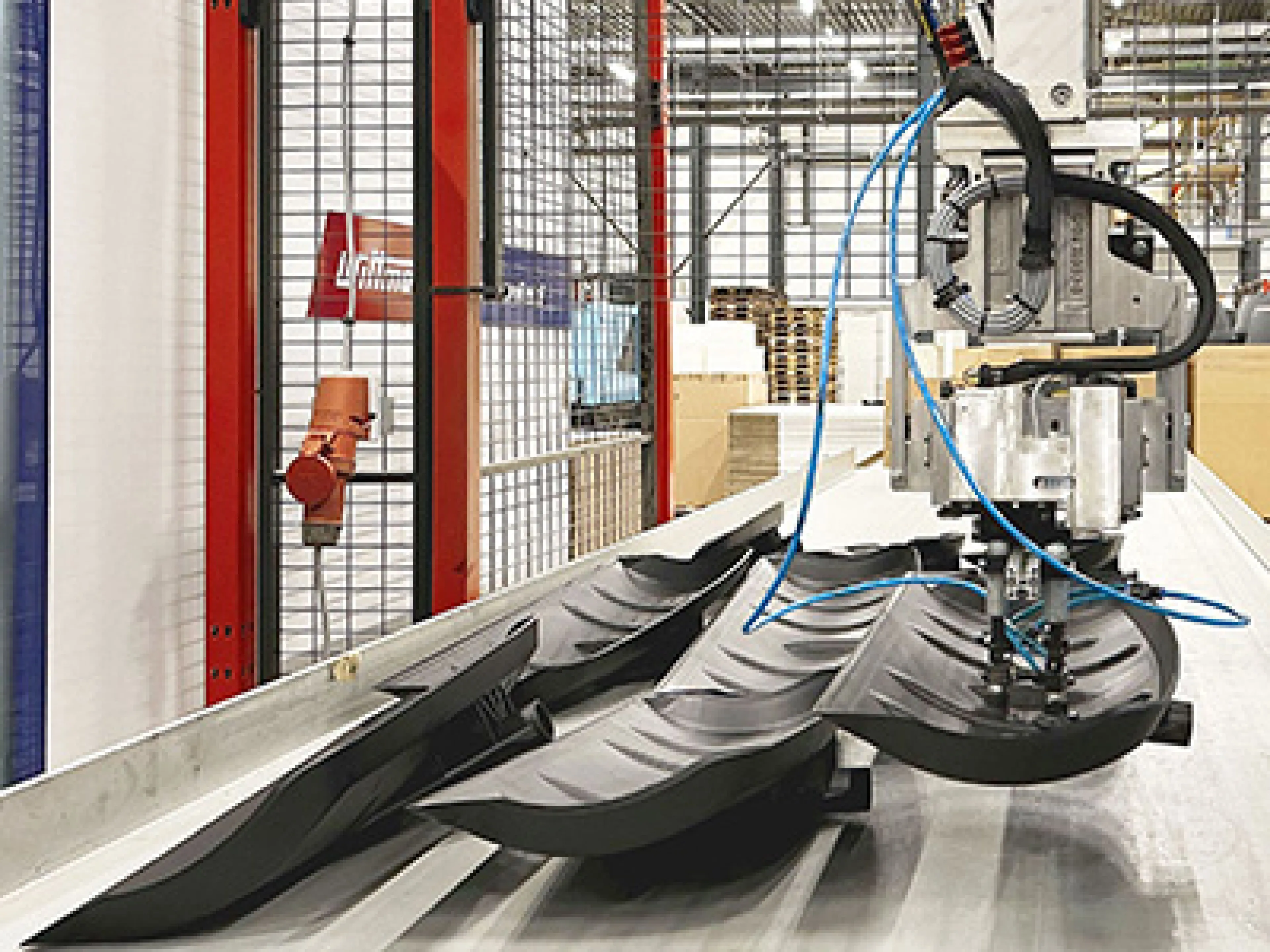

Small, slim PET bottles roll off the discharge conveyor on an "Ecopower 300" injection molding machine, produced in a 16-cavity mold. “PET looks like glass, but it does not break when it falls down,” explains Gula, which is why this material is playing a more and more significant part in cosmetics packaging. Twelve years ago, Bell was the pioneer in this field. “We were the first cosmetics producer to manufacture bottles for mascara and lip gloss from PET,” says Gula.

Today, PETG is the main material processed. This is a glycol-modified variant that is characterized by particularly high transparency and impact strength. It also has very good processing properties. With their standard universal screws, the Smartpower and Ecopower machines deliver excellent injection molding results with PETG. “Only the drying process presents a special challenge for this material,” reveals Gula. While normal PET is dried at temperatures of 160 degrees Celsius, PETG requires significantly lower temperatures between 60 and 70 degrees Celsius. “So, we have specially fitted the Wittmann Drymax dryers for our customer Bell with a cooling device,” says Bogdan Zabrzewski. It was important to Bell that the cooling could be switched on or off as required. This is because the dryers are also used flexibly for other materials.

“The Drymax from Wittmann has absolutely convinced us,” says Gula. ”We are reaching a dew point of minus 67 degrees Celsiuswith it. This has not been achieved so far by any other dryer model.” Zabrzewski explains the high performance of the Drymax dryer with the use of two desiccant cartridges. “The dryers deliver process air continuously, and drying air of constant high quality.” Thanks to counterflow regeneration, the dryer also features a particularly energy-efficient mode of operation.

Injection molding machines with short delivery times for “elastic production”

Bell's customer base is diverse. In addition to many long-standing customers who order large quantities well in advance, the company receives a large number of short-term orders with relatively small quantities every day. Added to this are the different requirements of the respective national markets. All in all, this requires a very large number of active tools and frequent tool changes. Waldemar Gula calls this high degree of flexibility, which Bell has to demonstrate on a daily basis, “elastic production.”

Production planning is made even more difficult by ever shorter innovation cycles. “Often a completely new packaging design emerges after just one year,” reports Gula. The company's own toolmaking department helps it to keep pace quickly and flexibly. However, the cosmetics manufacturer expects the same from its suppliers. “Short delivery times are vital for us,” emphasizes the production manager, who has already purchased one or two storage machines from Wittmann and bought a “Smartpower 300” directly from the trade fair stand at Fakuma.

Monomaterial packaging is trending

“We can fulfill any packaging request. Any shape and any color, from transparent to matte to high-gloss,” says the production manager. He reveals that high-gloss surfaces produced using injection molding are currently in high demand. Here, too, sustainability is a key factor, as metallization and chrome plating are increasingly being avoided to protect the environment and employees. Uncoated monomaterial packaging is also popular because it is easier to recycle.

“We bear a great ecological responsibility,” emphasizes Waldemar Gula. “It is important for us to include the consumers’ interests in all our decision-making”. On its website, for example, Bell posts information about sustainable production and instructions for correct disposal of the packaging, so that the plastic materials will be returned to the cycle. Every piece of cosmetic packaging leaving the Bell plant in Józefów is provided with a QR code. This gives consumers very easy access to information about the packaging materials used and the correct way of disposal for recycling. “This is the only way for a circular economy to function,” states Waldemar Gula, “by integrating the consumers into our network as part of the value chain.”