The Golden Triangle Polymers project is one of the world's largest ethane cracker plants. It will be built and operated by a joint venture between Chevron Phillips Chemical and Qatar Energy. The players will use Emerson's Plantweb digital ecosystem to optimize operations and reduce emissions. Emerson will use the ecosystem to provide automation technology, software and analytics for the plant. Operations are expected to begin in 2026.

The total cost of the joint venture project between Chevron Phillips Chemical Company LP and an indirect subsidiary of Qatar Energy is expected to be $8.5 billion. The project is a world-scale integrated polymer plant on the Texas Gulf Coast. It was designed using new technologies to reduce greenhouse gas emissions and is expected to cut them by about 25 percent compared with similar plants in the U.S. and Europe. “With its digital automation technologies, industrial software portfolio, and deep energy experience, we are relying on Emerson to help ensure a project of this magnitude operates safely and reliably, optimises energy use and mitigates emissions,” said David Godard, project director for the Golden Triangle Polymers Project.

World's largest ethane cracker

The Golden Triangle Polymers Project, located in Orange, Texas, includes a 2,080 KTA ethane cracker as well as two 1,000 KTA high-density polyethylene units. Polyethylene is used to produce durable goods and essential packaging to protect food and keep medical supplies sterile. “The Golden Triangle Polymers Project and the recently announced Ras Laffan Petrochemical Complex in Qatar are among the world’s largest ethane crackers, both leveraging Emerson’s digital automation technologies, software and expertise to promote safer, smarter and more sustainable operations,” said Ron Martin, Emerson’s president, Americas. “We are proud to support Chevron Phillips Chemical’s and QatarEnergy’s track record of building world-class, optimised facilities.”

Process control and safety technology from Emerson reduces project risk

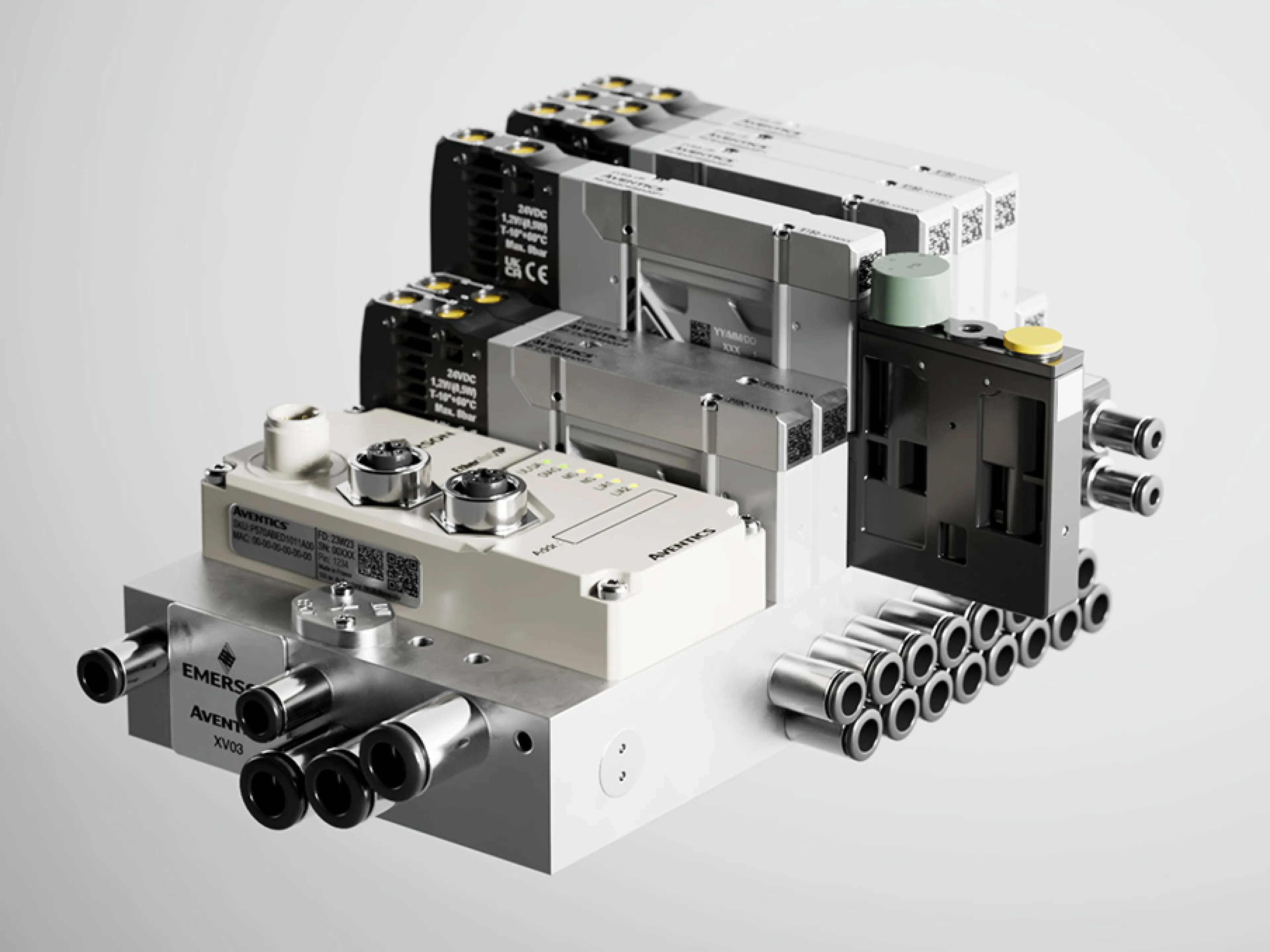

Emerson will deliver integrated process control and safety systems that leverage advanced predictive technologies to reduce operational complexity and minimise project risk through its "DeltaV" distributed control and safety instrumented systems, and Rosemount gas analyser and chromatograph solutions. The project also leverages Emerson’s "Mimic" and "AspenTech HYSYS" simulation software for operator training, energy management, safety analysis and operational optimisation. Emerson’s "AgileOps" operations management software and alarm management services will help staff monitor and maintain safety, alarms, and the control system to drive improved process and operational integrity.

The Golden Triangle Polymers Project is located about 113 miles east of Houston in the ‘Golden Triangle’ region of Texas that encompasses the city of Orange.