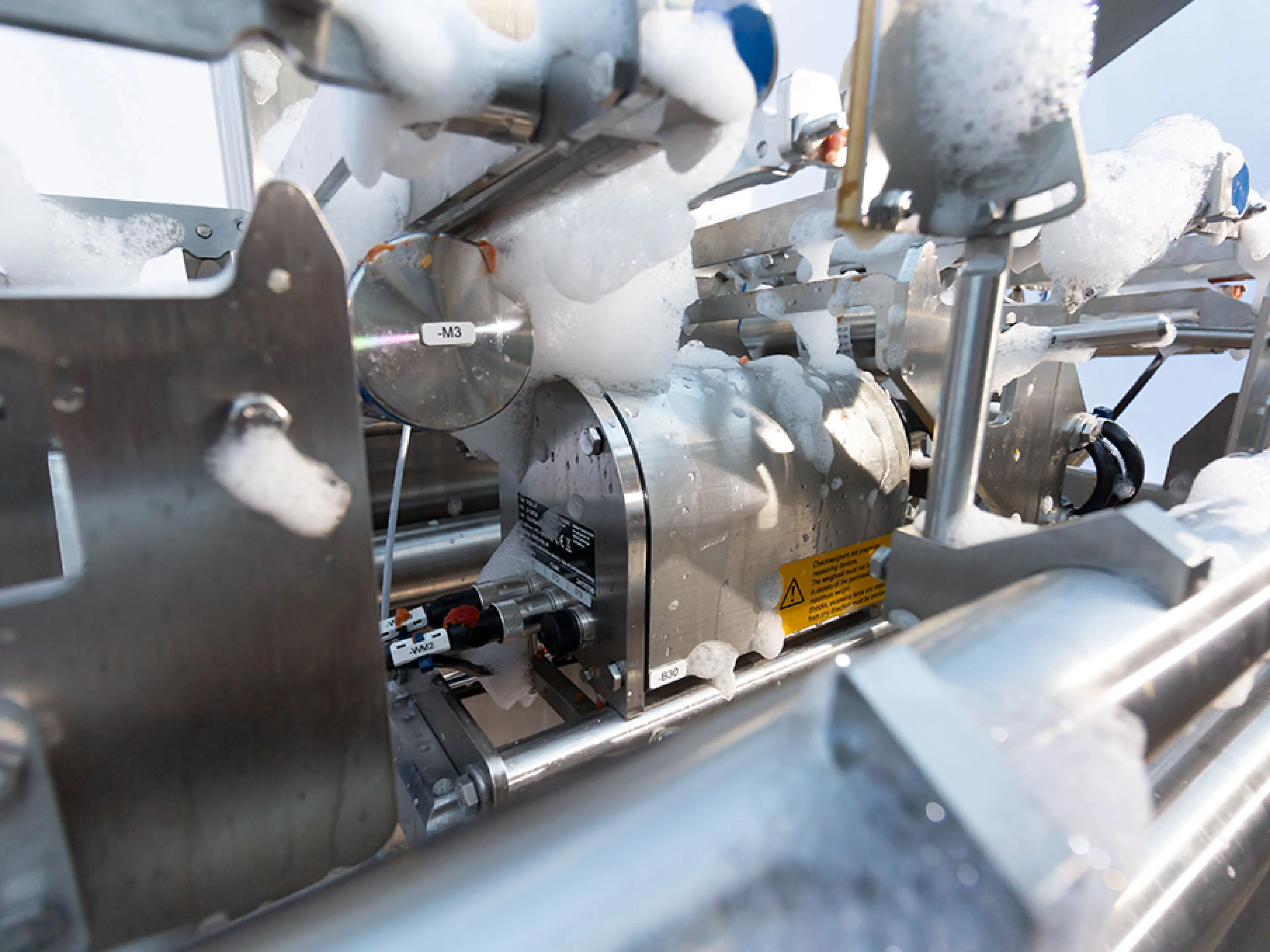

The new patented No Intervention Fines Return System (FRS) from Gea allows dairy and food powder producers to automate the cleaning-in-place (CIP) processes of their spray dryer fines return system, leading to reduced down time, improved working conditions and guaranteeing product safety.

In spray dryers, powder fines are often separated from the exhaust air via cyclones and bag filters. A fines return system returns the fines to the drying process, either for agglomeration or integration with the final powder outlet. Typically, cleaning cyclones and fines return systems first requires opening and dismantling the fines return system from the cyclones outlet. After cleaning, both must be reconnected again, which increases the risk of recontamination as well as the potential for mistakes in reassembly.

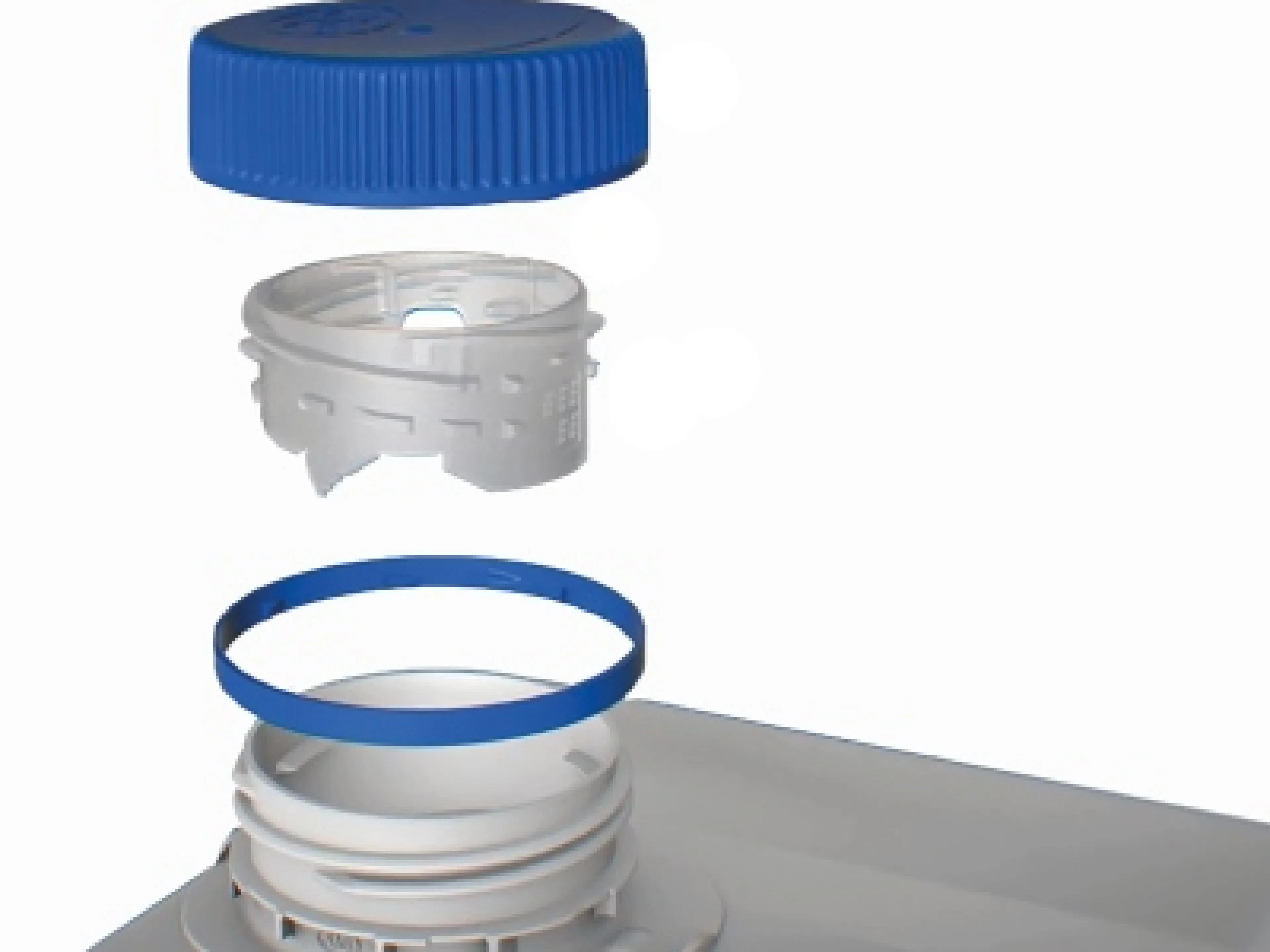

Explicitly designed for food and dairy spray dryers, the Gea "No Intervention FRS" uses patented valves to create a smoother and fully automated CIP process, which negates disassembly before and after cleaning. All connections within the fines return system remain closed and once cleaned, can directly be used for production. The valves were developed to comply with hygienic design criteria of the European Hygienic Engineering and Design Group (EHEDG) and have been proven to reduce the risk of CIP liquid leakage and overall contamination. “With our new No Intervention FRS, operators no longer need to worry about manual and time-consuming lifts and leakage risks associated with improper assembly,” explains Stig Møller Andersen, Product Manager at Gea. “By avoiding manual intervention before and after CIP, the process becomes quicker, safer, and more reliable.” Overall, the new Gea "No Intervention FRS" system promises a more efficient CIP process, improved working conditions, eliminates contamination risks and guarantees product safety. It is suitable for nearly all new Gea spray drying installations and upgrades.