Together, Sabic and Lubrizol Corporation have developed compatible material solutions that are well suited for a variety of applications in the consumer electronics and mobility industries, among others. Combining soft and rigid materials, these solutions can help customers advance their sustainability goals, improve protection in thinner and more vulnerable applications, and streamline manufacturing through part consolidation.

“Through our collaboration with Lubrizol, we provide material solutions with compatible chemistries that are ready to use which could accelerate time to market for our customers,” says Luc Govaerts, Technology Director, Sabic Polymers, Specialties BU. “This solution also enables our customers to develop more-sustainable applications, addressing an increasing trend across many industries.”

Joining complementary strengths and sustainable material portfolios of Sabic and Lubrizol

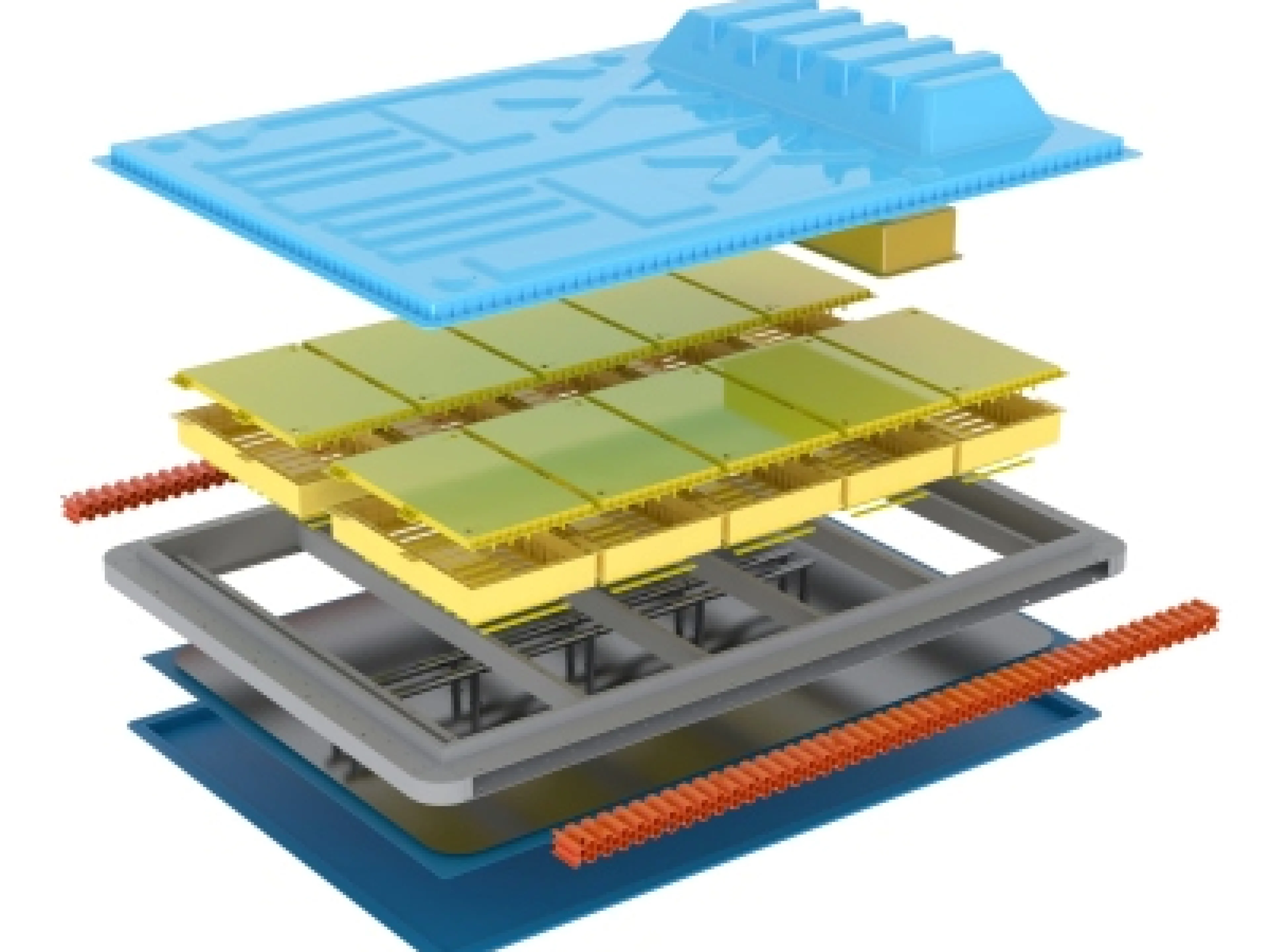

In these solutions, Sabic's specialty LNP compounds and copolymers act as rigid substrates, and Lubrizol's soft Estane Eco TPU (thermoplastic polyurethane) materials are two-shot injection molded onto the substrates. The thermoplastics from Sabic can enable thin-wall molding to reduce raw material consumption or provide chemical resistance for durability. Lubrizol's Estane Eco TPUs are formulated with bio-based content and manufactured in ISCC+ certified facilities.

Typical applications for these complementary materials include laptops, mobile phone cases and other electronic devices that require durability, drop protection and a non-slip surface. One potential application is a laptop case using glass-fiber reinforced LNP Thermocomp compound as the rigid substrate and Estane Eco TPU as the soft, overmolded polymer. The Sabic material offers high modulus, low warpage, good ductility and non-brominated/non-chlorinated flame retardance, as well as impact resistance and weatherability. The Lubrizol Estane Eco TPU offers chemical and abrasion resistance. These soft-rigid material combinations may also hold promise for industries other than consumer electronics, where features such as ergonomics or enhanced feel are required.

Higher demand of soft and rigid thermoplastic combinations

“We recognized an industry need for soft and rigid thermoplastic combinations that provide high performance and good bonding strength,” said Jane Cai, Senior Business Director APAC, Lubrizol. “But finding the right pairing can be time-consuming for customers. Lubrizol and Sabic combined our strengths and sustainable material portfolios to deliver proven compatible solutions that can help customers reduce their development time and costs and bring new designs and concepts to the market. With this approach, the possibilities are limitless.”