As a global standard, IO-Link opens up a wide range of possibilities for intelligent sensor integration in automation. This is exactly where Sick comes in. The new IO-Link master “SIG300” ensures flexibility, connectivity, and ease of use. This makes it a key component for efficient automation tasks. Special features include the integrated logic editor, which handles decentralized control tasks directly on the device, and the USB-C interface for intuitive configuration. Integration into heterogeneous device and fieldbus landscapes is also easy with the help of Sick's Function Block Factory. The IP67-certified IO-Link master has a total of eight ports and can process up to 102 digital signals. Unlike other IO-Link masters on the market, it also offers extensive functionality in a compact device.

IO-Link master acts as an intelligent data mediator

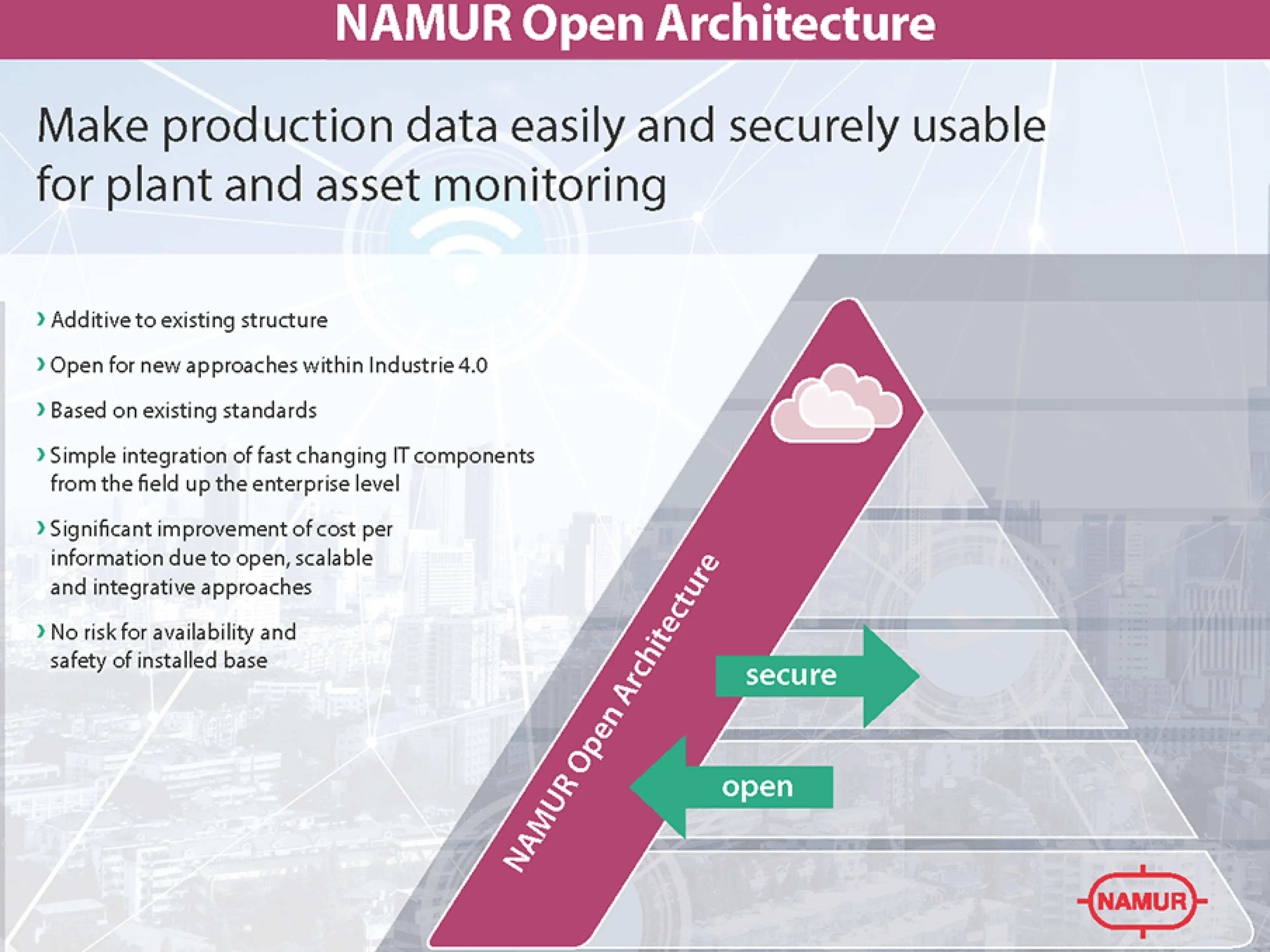

Increasing digitalization in industry requires seamless communication between machines and systems at the operational level (OT) as well as server and cloud environments in IT systems. The device takes on the central role of an intelligent data mediator. Using various interfaces such as JSON Rest API and MQTT, companies can integrate sensor and actuator data into IT and cloud platforms in real time. This is particularly relevant for applications such as condition monitoring, process control, and remote maintenance.

By supporting Ethernet-based fieldbuses such as Ethercat, Profinet, and Ethernet/IP, the IO-Link master ensures flexible integration into a wide range of control systems. This enables connection to programmable logic controllers (PLCs) without the need for time-consuming adjustments.

Plug-and-play implementation in heterogeneous device landscapes

Users of the “SIG300” can configure and parameterize connected IO-Link devices effortlessly and without additional software directly in the web interface via the integrated IODD interpreter. Customers can also access Sick's Function Block Factory online and generate suitable function blocks regardless of the manufacturer. This makes it just as easy to integrate the IO-Link master into fieldbuses and controllers from different manufacturers and seamlessly adapt it to the existing automation landscape.

Furthermore, the “Backup & Restore” function makes it much easier to replace connected devices. When a sensor or actuator is replaced, the master automatically transfers the previously saved device configuration to the new device without any additional effort on the part of the user. The same applies to the configuration, which can be duplicated and transferred to other devices. This saves customers time and money for programming that would otherwise be necessary.

Logic editor for efficient edge computing

As one of the few IO-Link masters, the device has an integrated logic editor. This allows IO-Link device data to be filtered and analyzed locally. This preprocessing enables logical operations such as counting, averaging, or limit value monitoring to be performed and data to be bundled for data transmission. Users benefit from increased responsiveness, reduced computing load in automation systems, and lower data transfer loads. This can lead to significant cost savings for cloud services, which are typically billed per data transfer.

IO-Link master as the key to intelligent automation

The process and device data is collected, managed, and seamlessly integrated by the IO-Link master. This opens up a wide range of applications in various areas of process control. In quality control, it detects production errors at an early stage by identifying deviations from defined sensor parameters. This reduces scrap costs, increases yield, and ensures consistently high product quality with lower resource consumption.

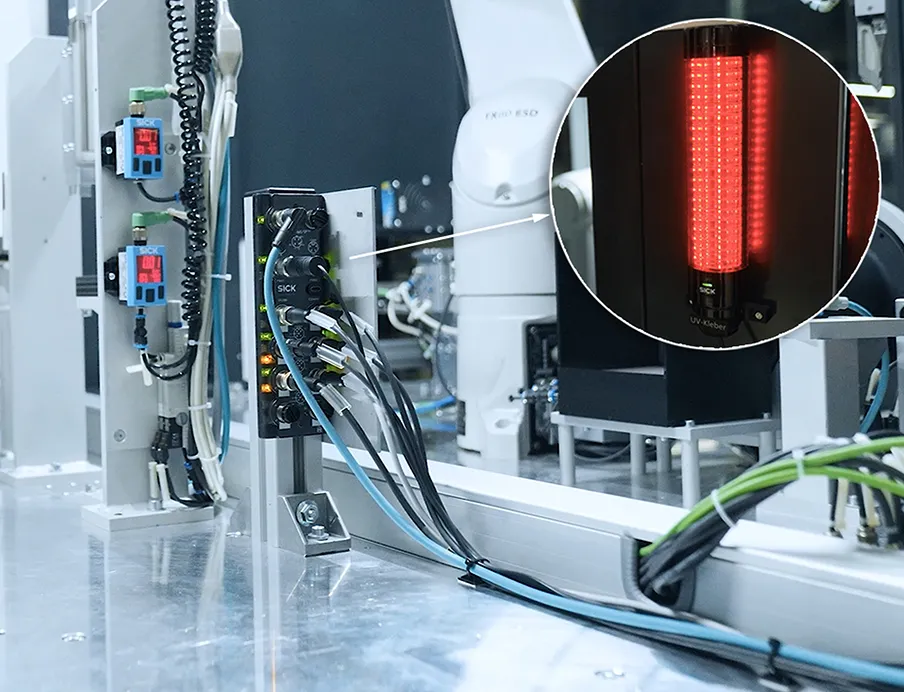

In automated assembly processes in particular, both product quality and process reliability can be significantly improved through data-based control of robots, grippers, and other handling systems. The transmitted sensor data is analyzed, enabling objects to be picked up and placed without errors. Critical changes are also detected in real time during machine condition monitoring and displayed via multiple channels. A connected signal light immediately alerts personnel at the operational level to a critical message, while the “SIG300” forwards the data in parallel to monitoring applications at the IT level. In addition, the master continuously monitors the status of the sensors so that maintenance measures can be carried out as needed. Bidirectional communication with the connected devices also enables efficient remote maintenance for maximum availability and minimal downtime. In summary, companies that want to future-proof their automation systems benefit from a powerful, scalable, and easy-to-integrate solution.