IO-Link

The certification of the IO-Link Safety specification by Tüv Süd is an important step for the industrial application of the safety standard. It marks the transition from development to market maturity and creates the basis for certified products. The following article shows what this means for manufacturers, integrators, and users.

The IO-Link Community has published its first Security Deployment Guideline to help end users assess and implement security measures for IO-Link systems. The document is aimed at operators of IO-Link infrastructures. The Security Deployment Guideline provides detailed instructions and best practices for deploying secure IO-Link systems. Topics include authentication, encryption, network...

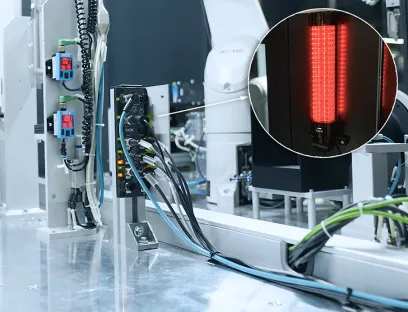

As a global standard, IO-Link opens up a wide range of possibilities for intelligent sensor integration in automation. This is exactly where Sick comes in. The new IO-Link master “SIG300” ensures flexibility, connectivity, and ease of use. This makes it a key component for efficient automation tasks. Special features include the integrated logic editor, which handles decentralized control tasks...

IO-Link is enjoying increasing popularity, with demand for the communications standard growing rapidly, especially in the food & beverage industry. The fieldbus-independent technology for point-to-point communication is easy to use and provides a cost-effective way to digitalize industrial plants. Endress+Hauser, a leading provider in the industry, offers a wide range of IO-Link products for a...