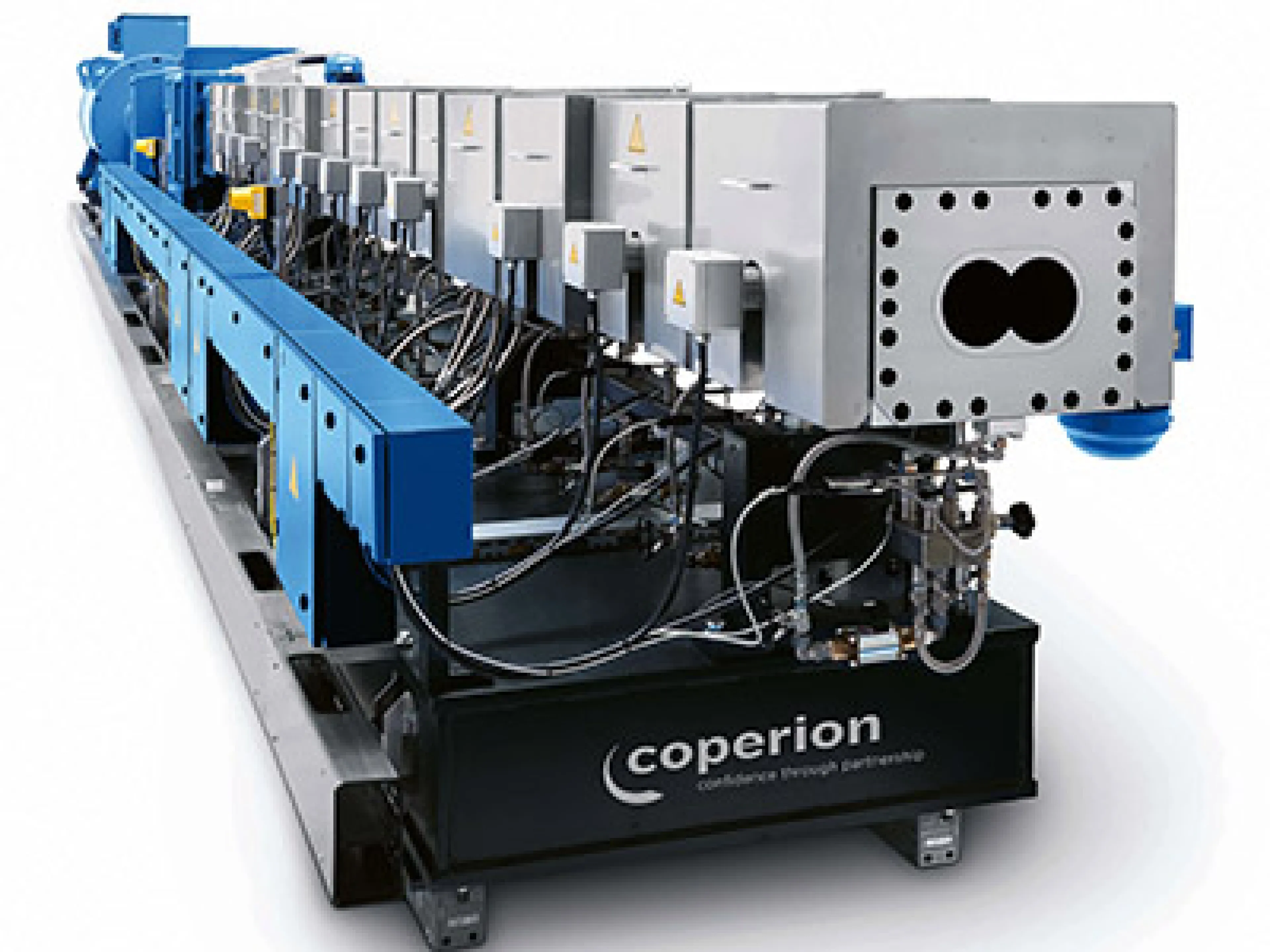

At the K 2025 trade fair, Erema is expanding its portfolio with a twin-screw extruder system specially developed for complex recycling tasks. The new “TwinPro” combines the in-house Preconditioning Unit (PCU) with a directly coupled twin-screw extruder. It thus offers a solution for low film bulk densities and high throughput rates.

Twin-screw extruder combines technology for high material diversity

At the heart of the twin-screw extruder is the direct connection between the PCU and the extruder. The input material is mechanically processed in the preconditioning unit. It is shredded, heated, dried, and compacted. The patented counter-current technology ensures a continuous material feed. The prepared input is fed directly into the twin-screw extruder, which ensures intensive homogenization. The system really shows its strengths when recycling multilayer films such as PE-PA or PE-EVOH: the targeted mixing of different polymer types in the extruder enables the production of high-quality regranulates with optimized mechanical properties.

Throughput and quality of very thin-walled post-consumer regrind

Another advantage is the processing of very lightweight materials with bulk densities of 30 to 800 grams per liter. The system does not require any additional units such as agglomeration or plugging devices. This makes the machine suitable not only for classic production waste but also for thin-walled post-consumer packaging, which is increasingly common on the market.

Erema cites sorted, hot-washed PP flakes from packaging such as yogurt cups as a typical application. Here, the very low bulk densities and possible moisture fluctuations of the material often pose a challenge. In these applications, the Preconditioning Unit enables a stable material feed while reliably removing residual moisture. In addition, the material is deodorized in the pre-process.

Production-ready and field-proven twin-screw extruder

After two years of development work and extensive practical testing, the company is launching the “TwinPro”, a solution suitable for series production. The system was developed in close consultation with customer requirements and specifically expands the Austrian supplier's existing range of technologies. You will find Erema at K 2025 in Düsseldorf in Hall 9, Booth C09.