Mettler Toledo

It starts with something small. A single drop of water in a crack, for example, or a fine tear that traps organic residues. It's a cleaning step that is often skipped in the rush to get the production line up and running again quickly. Then come the consequences: a contamination alarm, a product recall and a production stoppage. A seemingly minor design flaw can turn into a problem costing...

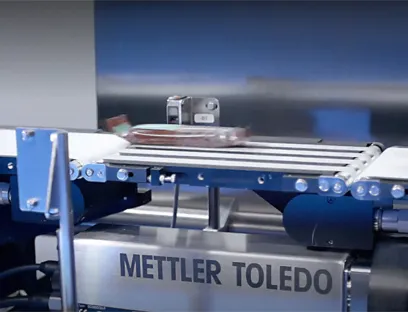

In the food manufacturing industry, waste reduction is vital for both economic efficiency and environmental sustainability. Manufacturers face rising demands to minimise waste, including the unnecessary disposal of products and to meet stringent regulatory requirements for product weight accuracy. With modern innovations in checkweighing technology, manufacturers can reduce waste at every stage of...

In an industry where speed and quality go together like crisps and salt, snack and confectionery manufacturers face the constant challenge of keeping up with consumer demand without sacrificing product integrity. Snacking continues to become more popular globally. According to Statista, it is even predicted that by the year 2030, global sales of savoury snacks could reach a value of $386.8 billion...

Maintaining high sample throughput while adhering to industry standards is increasingly important in food and beverage production. Automated systems can accurately characterize wine color for quality control while ensuring proper documentation and traceability of the results. Wine is subjected to a range of analyses during production and prior to sale, typically to meet the standards imposed by...

The new instrument analyzes liquid, translucent samples for their optical spectrum, color, and water parameters. Or any of the three. Operators speed up their processes and improve the quality of the results using Easy VIS. They, therefore, save money, time, and space. The instrument takes over the measuring tasks of up to three instruments: a colorimeter, a spectrophotometer, and special...

The new In-Tap from Mettler Toledo is based on the optical measuring principle of quenching of fluorescence light. Compared to conventional amperometric measurement it provides higher signal stability, lower maintenance re-quirements, no waiting time for sensor polarization, no electrolyte change, a very short response time and there is no dependence on the flow (no stop-of-flow effect).