Process Technology

Environment monitoring, Monitoring System, Temperature Monitoring, Humidity Monitoring, GxP Compliance, GxP, GAMP5, Monitoring Solution, Climate Control, Real-Time Monitoring

Handtmann is restructuring its corporate processes and fully integrating the Inotec product line into its global operations. In future, all relevant machine and spare parts processes will be bundled centrally at the Biberach site in Germany. The Reutlingen site will be expanded into a technology campus for process and line technology. This will strengthen Handtmann's innovative capabilities and...

With the "PACSystems RX3i CPS400", Emerson introduces a compact and scalable solution for SIL2 applications. The safety controller combines robust safety functions with flexible integration, thereby meeting key requirements in industrial automation. Support for common industrial protocols and easy configuration via familiar software environments make the system particularly attractive for OEMs and...

Interpack 2026 is fast approaching: from May 7 to 13, around 2,800 exhibitors will be presenting their innovations for packaging and processing in Düsseldorf. The focus will be on topics such as artificial intelligence, automation, sustainable materials, and new functionalities. Visitors can expect a comprehensive overview of current trends and practical solutions along the entire value chain...

Schubert has introduced a new solution at Fachpack that combines the advantages of cobots with the efficiency of classic packaging machines. With its compact design, high performance, and ease of use, the standardized, single-lane box erector sets new standards. Complemented by intelligent image processing and innovative adhesive technology, the system opens up new perspectives for automated...

With its new cGMP facility in Zurich, Siegfried subsidiary Dinamiqs has reached an important milestone in the manufacture of viral vectors. The company combines research, development, and clinical and commercial production under one roof, thereby significantly expanding its capacities. At the same time, Dinamiqs is entering into a collaboration with Seal Therapeutics to advance the development of...

The food industry is under pressure: rising labor costs, higher sustainability targets, and the need for more efficient processes. Middleby Food Processing has teamed up with Rockwell Automation to develop the first fully automated bacon production line. The solution reduces labor and water consumption, increases throughput, and sets new standards in the industry. This article shows the...

BASF Performance Materials has had all its European production sites certified according to REDcert2. The company now offers a comprehensive portfolio of sustainable high-performance plastics that replace fossil raw materials and reduce the carbon footprint. Engineering plastics, polyurethanes, TPU, and specialty polymers are now available to customers as certified mass balance solutions. For the...

With two focused acquisitions, Krones is further expanding its technological base in key market segments. The investments relate to both process technology and specialized solutions in can processing. The company is thus pursuing a clear strategy: expanding its portfolio through technological additions, tapping into new fields of application, and strengthening its position in global competition...

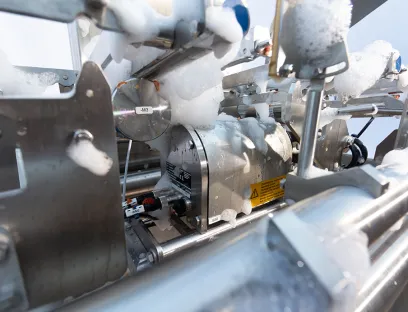

It starts with something small. A single drop of water in a crack, for example, or a fine tear that traps organic residues. It's a cleaning step that is often skipped in the rush to get the production line up and running again quickly. Then come the consequences: a contamination alarm, a product recall and a production stoppage. A seemingly minor design flaw can turn into a problem costing...