Energy efficiency in plastics processing is not just a sustainability issue, it is crucial for competitiveness. Data-based systems for analysis and optimization become increasingly important, especially in packaging sector, where unit costs must be calculated precisely. The injection molding company Filthaus uses the “iMAGOxt” energy monitoring system from Wittmann. It makes consumption transparent and implement targeted measures to increase efficiency.

Energy monitoring identifies hidden power guzzlers

An example illustrates the relevance of this. A production cell had an idle consumption of 300 watts, which is too much for standby mode. This was only revealed by “iMAGOxt.” The system records the energy flows of individual machines and systems in detail. It prepares the data in a clear format, and enables inefficient consumers to be identified and eliminated. “Without ,iMAGOxt’, we would never have noticed the high no-load consumption of this work cell”, says Stefan Filthaus, Managing Partner of the company. “Now we can address this issue, eliminate the hidden electricity consumers and thus save several thousand Euros per year.”

Cloud-based energy monitoring solution with real-time analysis

The software is cloud-based and collects measurement data at selected consumption points. This data is analyzed, translated into trends, and presented in the form of user-defined key figures. Energy consumption is not only understood as a measure of efficiency, but also as a strategic value for positioning the company. Large customers are increasingly demanding proof of the carbon footprint of the products they purchase, a requirement that can be met with "iMAGOxt". “Energy transparency is not just an internal efficiency indicator, but a marketable asset that strengthens the company's positioning and credibility and thus enhances long-term business resilience,” emphasizes Federico Colombo, sales expert at Wittmann Digital, the software house within the Wittmann Group.

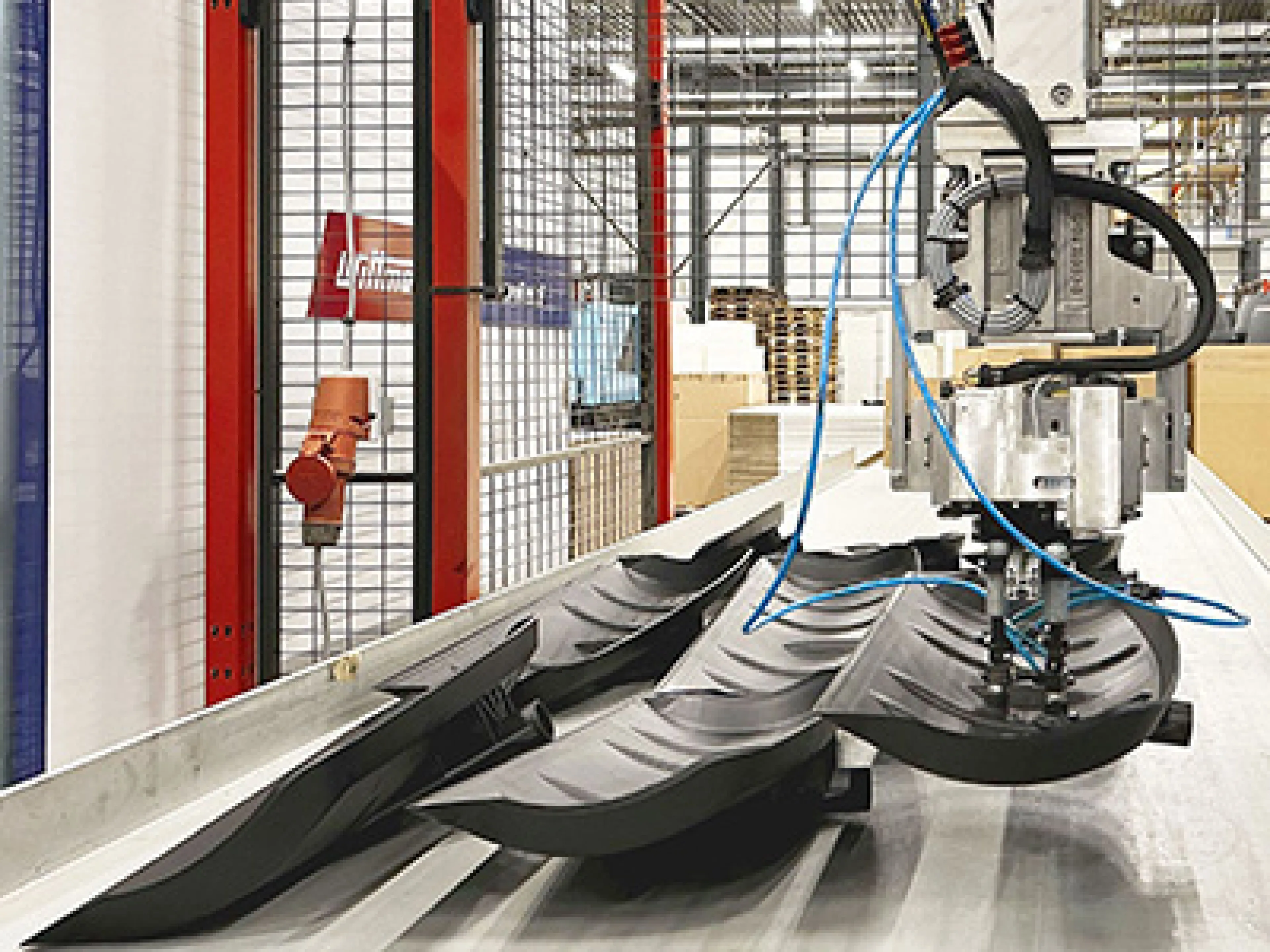

Filthaus applications in packaging and technology

The Filthaus product portfolio includes both packaging solutions and technical components. Both areas have high energy costs, averaging around 20 percent. Precise energy management is therefore crucial to offset cost increases and secure margins. Stefan Filthaus emphasizes: “In order to remain competitive, we must compensate the rising energy prices by reducing our energy consumption.” “iMAGOxt” enables a monetary evaluation of energy consumption throughout the entire production process.

Energy monitoring enables intuitive operation and high flexibility

In addition to the web-based software dashboard, Wittmann supplies suitable current sensors that can be installed independently of the machine type. This allows manufacturer-independent monitoring of energy flows. At Filthaus, 30 measuring points were defined, including injection molding cells, cooling systems, compressed air compressors, and the main connection to the plant. The difference between total consumption and production units can also be used to derive the consumption of administration, warehousing, and IT infrastructure. “’iMAGOxt’ functions system-independently and just as reliably with machinery systems consisting of many different brands”, explains Rainer Grießmann, design engineer at Wittmann Battenfeld Deutschland, who supports Filthaus in the implementation of software.

Transparency down to the device level

The graphical displays in the system allow energy consumption to be evaluated by time intervals or per production cell. Filthaus uses the values to calculate CO2 emissions, energy costs, and unit prices. The ability to access all data on the go without an app is particularly advantageous. This allows decisions to be made regardless of location.

In addition to the injection molding production cells, two cooling systems and the two large compressed air compressors were also integrated into the energy monitoring system. Furthermore, the main connection has been defined as a separate measuring point. The aim was to determine the electricity consumption of administration and warehousing, including lighting, IT infrastructure, heat pumps, and other non-production-specific consumers. This was to be done based on the difference between the total power consumption in the building and the production equipment. A total of 30 measuring points were installed and networked at Filthaus.

Energy monitoring of individual consumption

The software allows individual consumption to be displayed either in kilowatt hours or tons of CO2, based on one kilogram of processed material. These values are lower when the sun is shining strongly, as Filthaus invested in a photovoltaic system in 2024. “In summer, there are days when our production is running completely independently of the public power network”, says Stefan Filthaus. “This reduces the CO2 footprint of the products and saves money.” The managing director is convinced that measures for greater sustainability must always pay off financially.

Analyzing and avoiding power peaks

A current project at Filthaus is focused on reducing power peaks, which can lead to increased supply costs. “iMAGOxt” provides the data needed to analyze causes and adjust load profiles. Precise analysis allows targeted measures to be derived to reduce peak demand.

Collaboration with Wittmann

Close cooperation with Wittmann's software house, located just a few meters away, promotes rapid implementation and goal-oriented coordination. The constructive exchange with Wittmann's development teams contributes significantly to the continuous further development of the system. “We can always arrange spontaneous personal meetings at short notice”, says Grießmann. But for Stefan Filthaus, there is more to the excellent cooperation: “We talk to each other on equal terms, and all of our contact persons are quick and target-oriented in implementing projects. But what I appreciate most is our easy-going mutual interaction.”