This summer, Arburg took another important step towards an even greater global presence. The company has opened a new branch in Ho Chi Minh City in Vietnam. The main aim is to bring Arburg's products and services closer to local customers in Vietnam. With the new subsidiary in Vietnam, the machine manufacturer is now present with its own organizations at 36 locations in 26 countries worldwide.

Together with trading partners, Arburg is represented in over 100 countries. In this way, the company ensures that all required specialists are always available locally when customers need them.

Growing demand in Vietnam

The decision to establish the subsidiary is based on the intention to make offers and services for this growing market more easily, quickly and safely accessible. David Chan, Managing Director for Southeast Asia, says: "Vietnam, with its strategic location in the Asean region, is an important location for the further growth of our company. This move will allow us to further expand our already strong presence in the Asean markets. The plastics industry is constantly changing. With our new presence in Vietnam, we can fully meet the needs of a rapidly developing market. We can adapt to local demand and serve customers directly with innovative solutions and quality products from the Arburg portfolio."

Arburg improves support for the Southeast Asian market

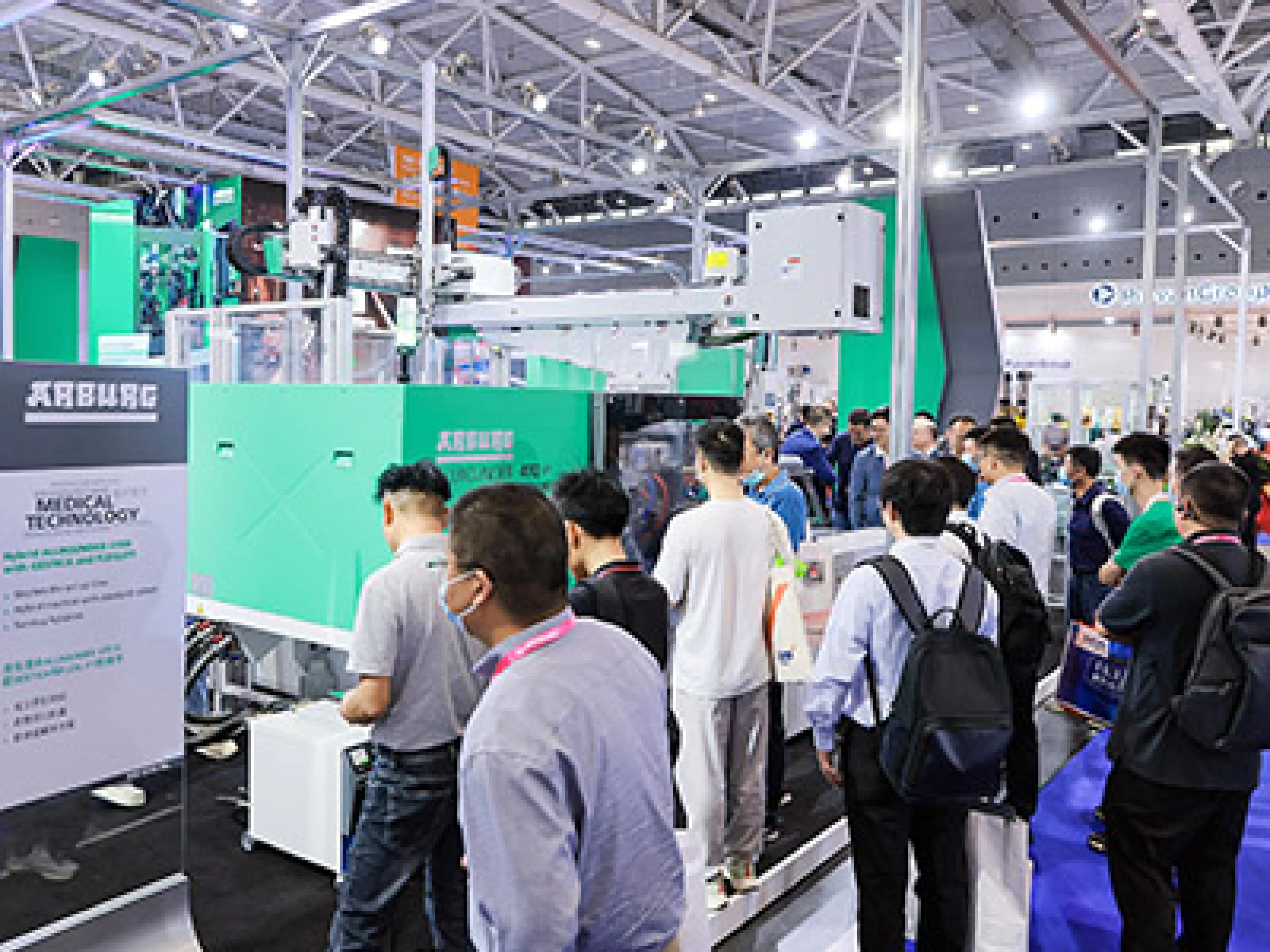

With its presence in Vietnam, Arburg is committed to a further improved and more sustainable future for plastics production in the Southeast Asia region. The new subsidiary has a dedicated team of sales and service professionals who have an equally deep understanding of both Arburg technology and the local market. It is also networked with the other subsidiaries in the Asian market and the Arburg Technology Factory (ATF) in Pinghu, China. The offering includes the highest service quality and advanced plastics technology as well as the exchange of best practices within the industry. This portfolio makes the manufacturer of injection moulding machines a trustworthy partner for practical, individual processing solutions.