The Fraunhofer Institute for Photonic Microsystems IPMS is one of the leading research institutions for the development and testing of electronic, mechanical and optical components and devices and their integration into intelligent systems. The Fraunhofer IPMS will again be present at the Sensor+Test 2022 trade fair in Nuremberg. The institute will showcase some of its latest research and developments, such as a new technology for measuring gas mixtures based on micromechanical ultrasonic elements (MUT) or an innovative electrochemical analytical chip for the smallest analytical quantities.

The core objective of the research work of Fraunhofer IPMS is to extend the functionality of customers' products through the use of innovative technologies, components and systems. With its innovative Micro-Electro-Mechanical Systems (MEMS) and Micro-Opto-Electro-Mechanical Systems (MOEMS) new applications are enabled by improved properties, smallest dimensions, energy efficiency and additional functions. Some of the latest developments, which the institute will be presenting at the Sensor+Test trade fair in Nuremberg from May 10 to 12, offer solutions for a safe more environmentally friendly use of hydrogen in natural gas pipelines, for monitoring patients outside hospitals, or for analyzing the smallest quantities of analytes.

The use of hydrogen as an energy carrier is an essential element for the energy transition. Hydrogen will be widely available as a mixture with natural gas in the German pipeline network to enable its use in households and industry. Given the different calorific value of hydrogen compared to natural gas, it is essential to monitor the hydrogen content in order to adjust combustion control. Currently, the characterization of gaseous systems is mainly realized by gas chromatographs. However, this method is too expensive, especially for smaller gas systems at end users. Therefore, within the MUT4H2 project, Fraunhofer IPMS is developing for the first time a new technology for measuring gas mixtures based on micromechanical ultrasonic elements (MUT). These enable compact and cost-effective real-time analysis as well as decentralized monitoring or control of local systems. More detailed information will be available to visitors at the Fraunhofer IPMS booth and in a presentation by Jorge Mario Monsalve Guaracao, MEMS Designer at Fraunhofer IPMS, on May 11 from 10:30 to 11:00.

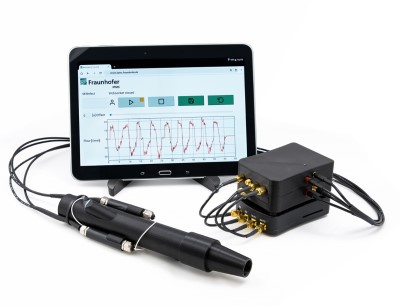

Within the cluster project M3Infekt initiated by the Fraunhofer-Gesellschaft, Fraunhofer IPMS developed an important contribution to the development of a mobile and powerful spirometer using its advanced CMUT ultrasound sensor technology. The device for analyzing lung function is part of an AI-controlled, decentralized patient monitoring system, which can be used outside of hospitals and intensive care units. The aim is to reduce the burden on hospital care.

Furthermore, the researchers of Fraunhofer IPMS present an electrochemical analytical chip, that is easy to handle and can be used for the smallest analysis quantities, for example in material development, the production of organic semiconductors or in the analysis of body fluids. Visitors will also learn more about the latest compact and ultra-compact near-infrared (NIR) spectral analysis systems. Whether freshness testing of food, sorting of plastic objects in recycling or determination of type and concentration of raw materials in pharmacy. The miniaturized spectroscopy systems developed by Fraunhofer IPMS are used in a wide range of applications. They can be flexibly adapted to different spectral ranges in the design process. Visitors at Sensor+Test will find the Fraunhofer IPMS booth at #1-150/4.