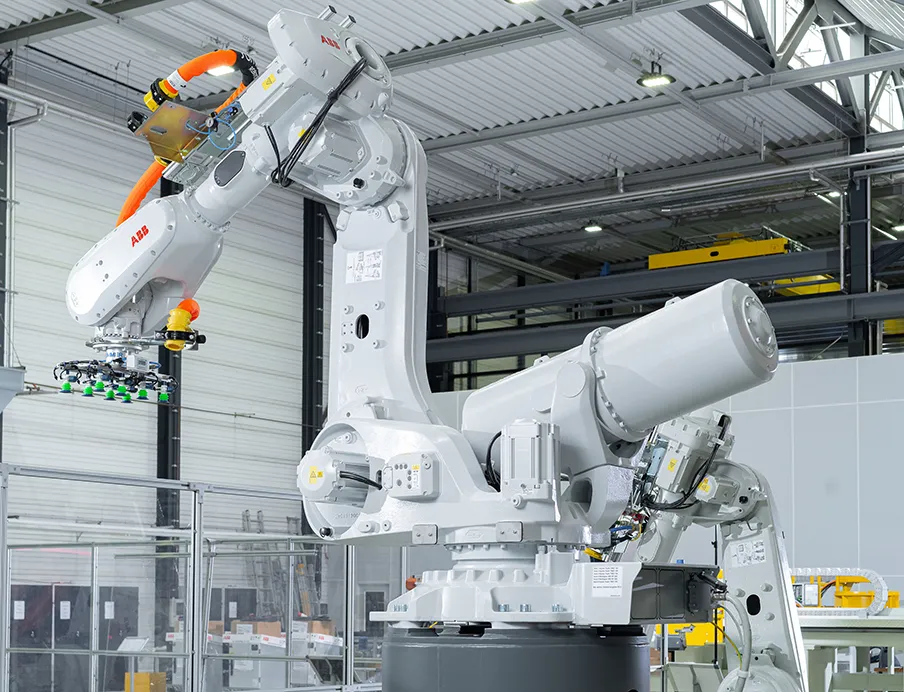

ABB has expanded its portfolio of industrial robots with the "IRB 6730S", "IRB 6750S", and "IRB 6760" models. The new large robot models are characterized by high payloads, flexible installation options, and optimized mobility. ABB is thus targeting applications in the automotive and foundry industries as well as in general mechanical engineering.

Performance increase through “OmniCore” control

All new robots are operated with the "OmniCore" control. This enables energy savings of up to 20 percent and achieves high path accuracy, such as with the “IRB 6750S” with up to 0.9 millimeters. At the same time, the control supports efficient and sustainable plant planning.

ABB strengthens market position in industrial robots

“The launch of our new robots supports our vision that ‘versatility' will be the defining factor for robotics in 2025,” said Marc Segura, President Robotics Division at ABB. “This market-leading range of industrial robots and variants, coupled with our comprehensive portfolio of mechatronic platforms, cobots, and AMRs, ensures we are ideally placed to support our customers as we enter a new world of increased productivity and flexibility. And our automation solutions can help companies to address challenges such as labor shortages while supporting sustainable operations.”

Efficiency for press lines and production lines

The "IRB 6760" is specially designed for press feeding and offers up to 15 strokes per minute. This makes it particularly suitable for the automotive and electronics industries. The "IRB 6730S" and "IRB 6750S" console robots can be installed above the work area, enabling higher robot density while optimizing space.

Cooperation between ABB large robots

The flexibility of the portfolio is also evident in combined applications: Ten “IRB 6730S” or “IRB 6750S” console robots can work together with eight floor-mounted robots of the “IRB 6710” to “IRB 6740” series. This allows the number of weld points on a vehicle body to be increased from 70 to 80 in just 15 seconds. The modular design with common spare parts and services also helps to reduce operating costs in the long term. ABB presented the new industrial robots at Automatica 2025 in Munich.