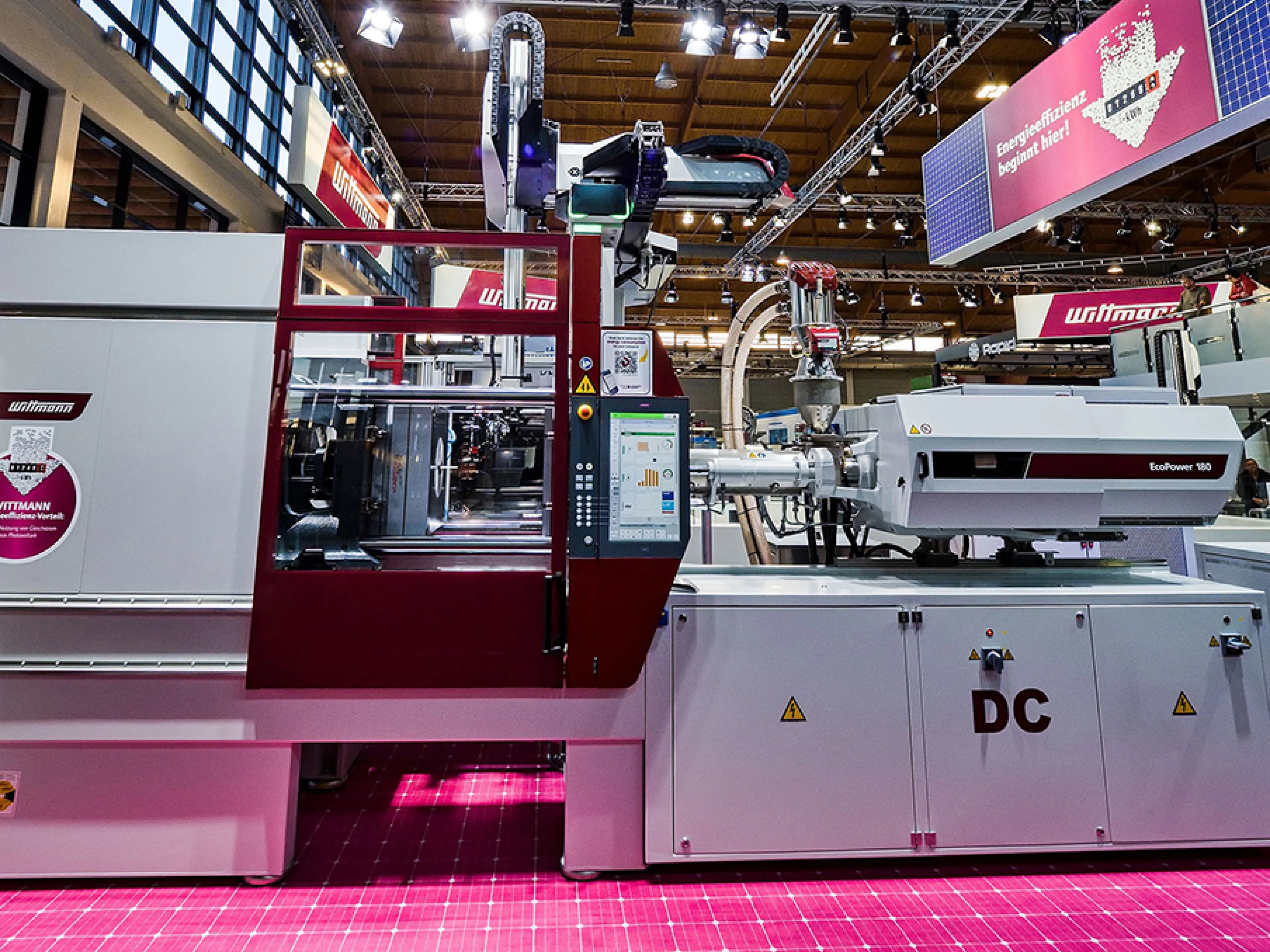

At Drinktec 2025 in Munich, the Wittmann Group will be showcasing a high-performance system for manufacturing plastic closures. The leading international trade fair for the beverage and liquid food industry will take place from September 15 to 19 at the Munich Exhibition Center. The focus of the trade fair presentation will be a high-speed electric injection molding machine of the “EcoPower Xpress” type. The system is specially designed for short cycle times and high process reliability. Thanks to fully electric drives for injection, closing, and opening, it achieves injection speeds of up to 650 millimeters per second and injection pressures of up to 2,500 bar.

Injection molding machine produces HDPE closures

The application presented is aimed at manufacturers of caps and closures for beverage bottles. Short strokes, fast mold movements, and reliable dosing are crucial in the production of standard closures made of HDPE. The "EcoPower Xpress" meets these requirements with a cycle time of less than 2.5 seconds and low energy consumption.

Machine equipment of the injection molding machine and materials used

During the trade fair, an "EcoPower Xpress 160/1100+" injection molding machine with a 32-cavity mold from HTW in Austria will be in operation. The production of HDPE caps with a diameter of 29/25 millimeters and a weight of 1.35 grams will be demonstrated. The material used comes from Totalenergy's Onetech Belgium. The production cell is supplemented by a conveyor and a mold cavity dehumidification system from Wittmann.

Automated post-processing and quality assurance

After demolding, the finished closure caps are transported via a conveyor belt integrated below the mold into an automation system from IMD Vista. In this system, the closure caps pass through cooling, orientation, separation, and inline quality control stations. Parts detected as rejects are automatically sorted out before the parts that are of perfect quality are fed into the packaging system. You can find Wittmann at Drinktec in Hall C6, Booth 501.