The recycling of post-consumer input materials is subject to a wide range of fluctuations. This poses major challenges for recycling systems and melt filters in particular. The recycling machine manufacturer Erema offers two filter models in different sizes, designs and performance variants: the "Erema SW RTF" backflush filter and a laser filter. The manufacturer has now developed the intelligent Discharge-Pro control system for the laser filter. This allows the company to improve process stability over the entire runtime and react automatically to fluctuations in the recycling process. This reduces melt loss by up to 50 percent.

The new discharge control of the laser filter significantly increases the degree of automation and automatically compensates for fluctuations in the input material. By adjusting the speed of the scraper disc and discharge screw as required, Discharge-Pro ensures uniform thickening during melt filtration. This is a decisive parameter for a constant and economical process. "The new Discharge-Pro control system automatically determines the optimum process setpoints and ensures that these are maintained during the whole operating period of the laser filter," explains Robert Obermayr, Head of the Powerfil business unit at Erema. "This is made possible using fully automatic reinitialisation, which is time and/or event driven."

Up to 50 percent less melt loss

On the one hand, the innovative discharge control system reacts to selective disruptive factors, such as

- Contamination peaks: The control system automatically adjusts the speed of the stripping star and returns to the determined target value as soon as the overload of contaminants has been discharged.

- Throughput reduction: The new laser filter control recognises significant changes in throughput and automatically adjusts the discharge rate so that the degree of thickening remains constant during filtration.

- Viscosity increase: As soon as the melt has a higher viscosity and thus generates a higher differential pressure at the filter screen, Discharge-Pro automatically determines a new setpoint value and thus keeps the discharge rate constant.

Intelligent discharge control adjusts the setpoint automatically

Longer-term changes are also taken into account. The current condition of the filter screen is taken into account: Over the course of the screen's utilization period, the open screen area decreases, causing the differential pressure to increase even if the feed material remains unchanged. The intelligent control system reacts to this with a permanent automatic adjustment of the set value and thus continues to ensure an optimum thickening ratio.

"Our new laser filter control system delivers greater efficiency and more stable processes for our customers and is particularly user-friendly," emphasises Robert Obermayr. The machine operator no longer needs to readjust the filter, which reduces the personnel time required. Depending on the application and degree of contamination, Discharge-Pro reduces melt loss noticeably. "We have been able to achieve up to 50 percent lower melt losses for our customers compared to the previous Erema laser filter control system," says Obermayr.

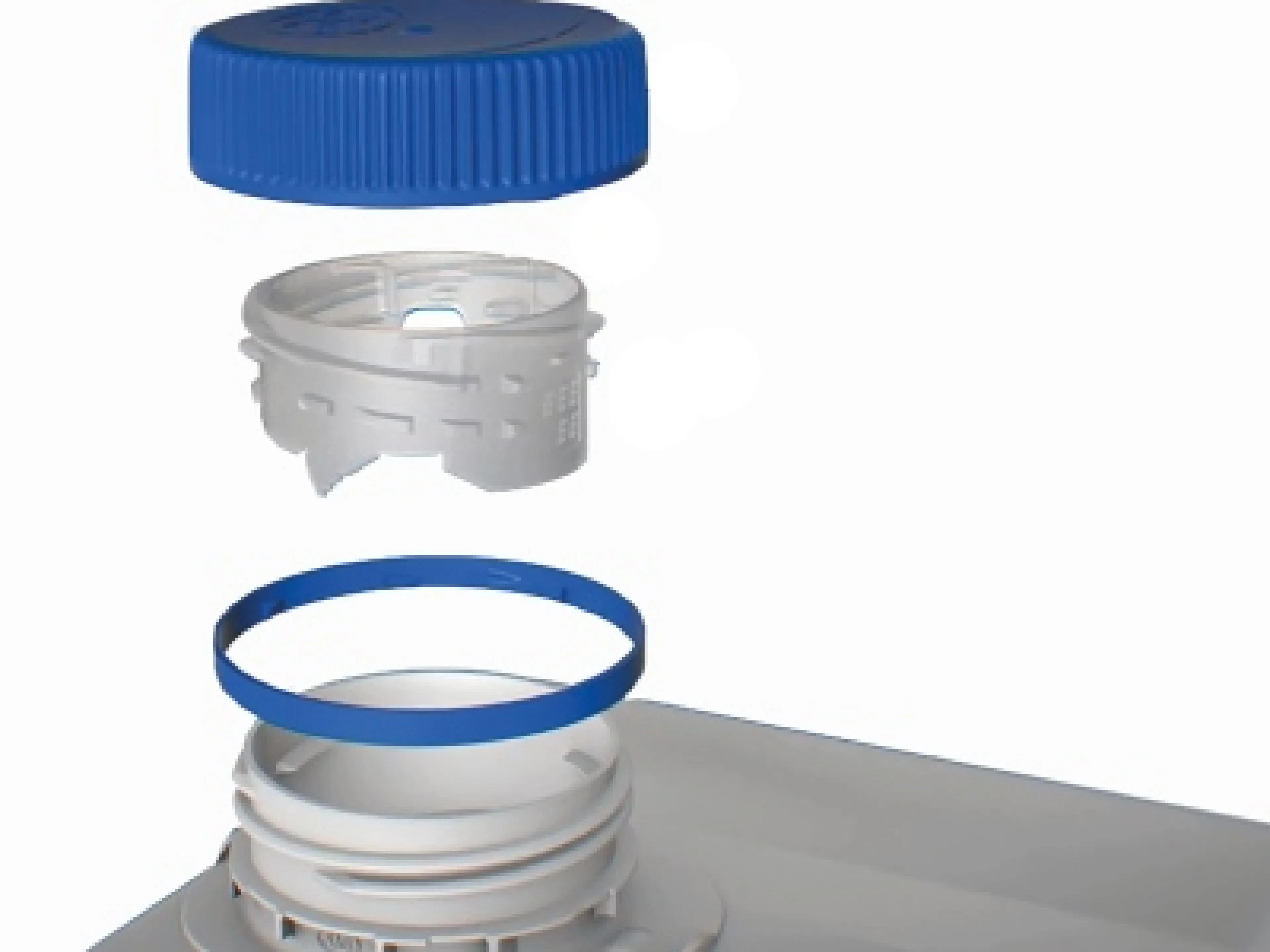

50 percent more screening surface

Another innovation in Erema's filtration technology is the size 2/406 laser filter, which has a 50 percent larger screen area than the 2/356 laser filter. According to the manufacturer, the increased surface area means that a significantly higher quantity of molten plastic can be filtered per unit of time. This is advantageous for applications where throughput is a priority.