With global demand for plastic polymers continuing to rise, one thing is clear. Only a functioning plastics circular economy can meet this demand sustainably in the long term. The key to success lies in pure recycled material that can be fed into plastics production and processing just like virgin material.

Sesotec relies on smart solutions for the plastics circular economy

Sesotec follows the guiding principle “Economy meets Ecology.” The aim is to combine economic efficiency with ecological responsibility. Poorly sorted material streams not only cause financial losses but also prevent the environmental benefits of a functioning circular economy from being realised.

Efficient technologies along the value chain

The company develops systems that minimise energy and air consumption, are easy to operate, and deliver high-quality recycled material. Success is driven not only by advanced technology but also by the expertise and dedication of the company’s employees. In the application centre, sorting department, and service team, specialists work every day to simplify processes and create efficient solutions for customers.

High-tech sensor technology and AI for the plastics circular economy

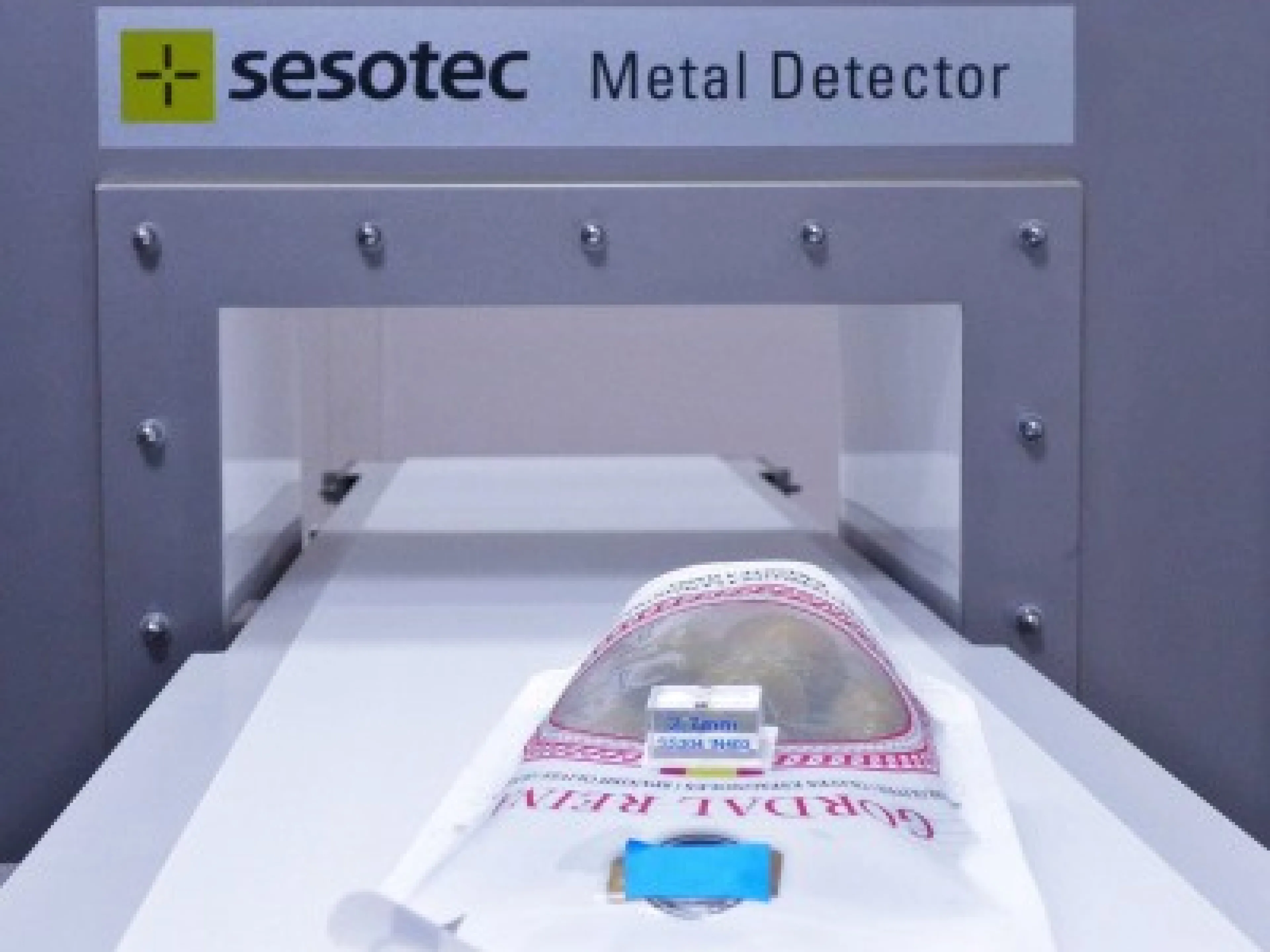

In its in-house technical centre, Sesotec conducts product tests for customers from around the world. Here, visitors can experience the combination of state-of-the-art high-tech sensor technology with Sesotec’s “SUSTAiN Technologies”. This is an innovative fusion of advanced sensors and artificial intelligence that enhances sorting quality and process stability.

A functioning plastics circular economy requires trust, quality, and process stability

“A functioning circular economy naturally requires the best technology, but it also needs trust, quality, and process stability,” explains Stefan Eggersdorfer, Head of Service Sorting at Sesotec. “Our mission is to pave the way for our customers to achieve greater sustainability and economic success with smart solutions. Together, we are shaping a future in which plastic consumption and recycling go hand in hand, profitably, sustainably, and globally.”

A holistic approach for greater material efficiency

From incoming goods inspection through to material-specific plastics sorting, and on to analysis and documentation of outgoing goods, Sesotec offers technologies for every stage of the process. This integrated approach, combined with many years of experience, ensures higher material yield, stable processes, and economic success for companies in the plastics industry. These are all essential factors for a functioning plastics circular economy.