Sappi Europe has invested a double-digit million amount in a new plant for the production of new high-barrier papers. This includes a new type of barrier coating line. Recently commissioned at the Alfeld site in Germany, the in-house solution will produce high barrier papers for recyclable packaging of food and non-food applications. Visitors to Interpack 2023 can learn more about the potential applications of the new coating machine.

For more than ten years, Sappi has been producing packaging papers with integrated barriers against oxygen, grease, water vapor, mineral oil and aromas, as well as heat-sealing properties. These papers provide protection for packaged products. At a time when the packaging industry is increasingly required by consumers, retailers and legislators to offer sustainable materials and processes, the manufacturer's commitment to paper-based, recyclable flexible packaging solutions addresses this megatrend towards more sustainable packaging solutions.

Double-digit million investment in barrier coating plant

The company has invested a double-digit million amount in a completely new type of barrier coating line for the production of barrier papers, which was recently commissioned at the Alfeld site. Marco Eikelenboom, CEO of Sappi Europe, emphasizes: "We offer brand owners and converters fibre-based, recyclable packaging solutions that enable them to achieve their sustainability goals and contribute to the circular economy" According to the company, the new coating line is a world first and significantly increases the share of the company's specialty barrier papers available on the market. The investment also includes a coating kitchen, roll finishing and automated handling system, providing scalable, high production volumes of 300 million square meters, as well as opportunities to develop customized solutions and continuous coating innovations.

Renewable, recyclable packaging

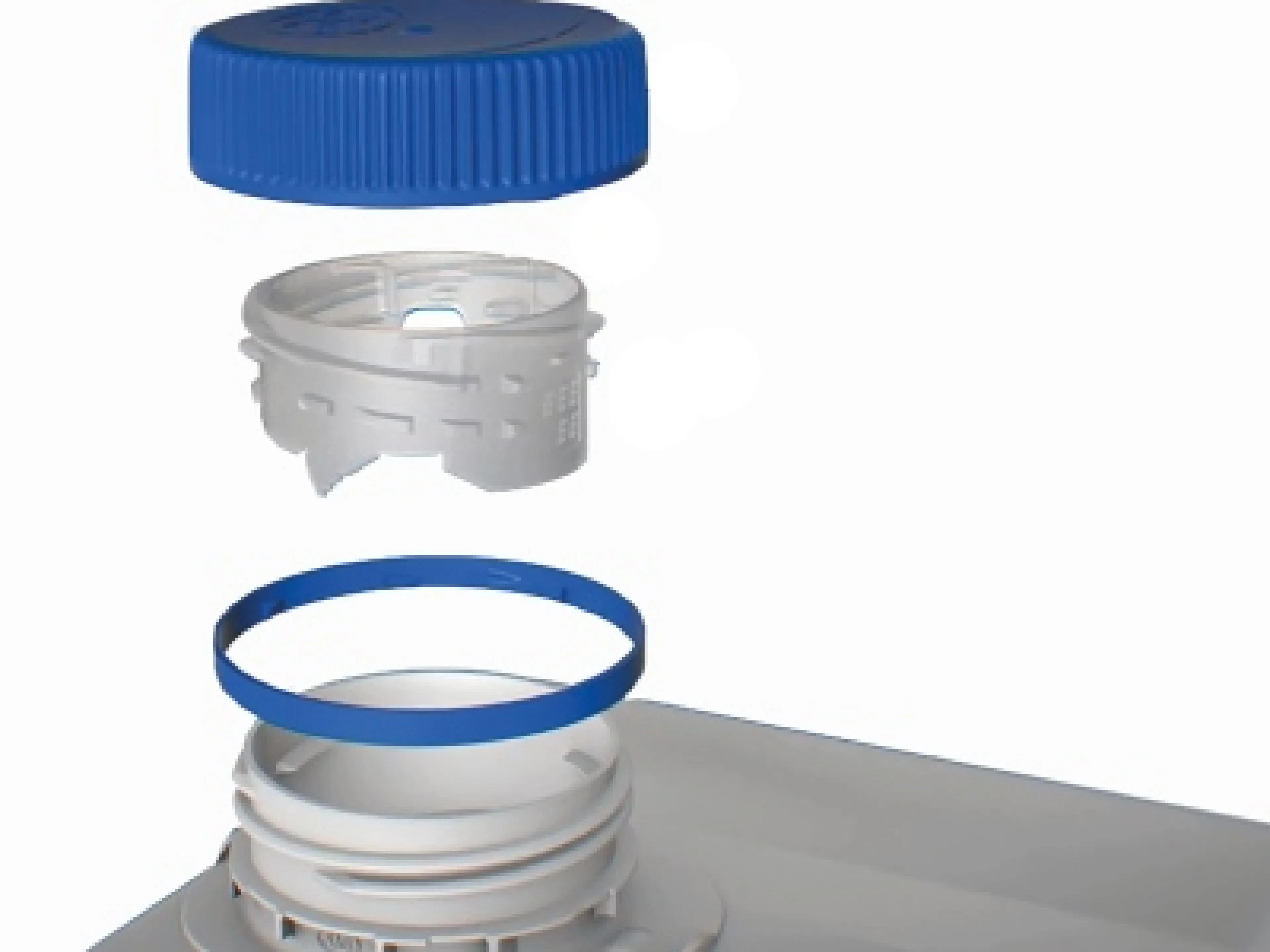

Different coating technologies can be used on the new machine depending on the need and application. The manufacturer uses water-based dispersion technology for multi-layer coating of high-barrier papers. Sappi plans that its in-house development of coating formulations in the special coating kitchen will also be used on the machine in the future. In cooperation with customers, this will develop further alternatives to non-recyclable packaging for the market, which will benefit both consumers and brand manufacturers.

Sappi at Interpack

You will find Sappi at Interpack 2023 in Dusseldorf in Hall 8A at Stand B35.