At the beginning of the year, Elasto took an important step toward automated injection molding production. With a new central material supply system from Wittmann, previous manual handling process was replaced by a closed, automated system. This modernization is part of an extensive investment program with which Elasto aims to make its production in Germany competitive in the long term.

The medium-sized company from Sulzbach-Rosenberg is one of the largest manufacturers of promotional items in Europe. Its product range includes giveaways, high-quality everyday items, and lifestyle and sports products. Since its founding, the company has grown steadily and is increasingly focusing on sustainability and regional value creation in production. “For promotional items made of plastics, major brand owners increasingly turning to European production,” reports Marcus Sperber, who is the second generation to run the family business.

Elasto invests €12.5 million in modern production and logistics

Elasto manufactures more than 600 of the approximately 1,400 products it offers in Germany, primarily plastic items. The machinery consists of 18 injection molding machines, one stretch blow molding machine, and one blow molding machine. A new production and logistics center was built to expand production, with an investment of around €12.5 million. The production hall was also completely renovated and converted to create more space for modern machines and automated processes.

Before modernization, granulate containers were placed next to the injection molding machines. The material was filled into the hoppers manually. Operations manager Markus Rösel describes the old process: “Two staff members were fully occupied with refilling granulate.” At the same time, this meant that there was a lack of personnel capacity for other tasks.

Central material supply as an efficiency driver

At the heart of the new production facility is now a large central material supply system from Wittmann. “With this central material supply system, we have also provided the structural basis for further growth,” emphasizes Sperber. Several high-performance dryers and 750-kilogram containers for the most important types of material are available. The system first transports granulate via a closed piping system to a coupling point. From there it goes on to the processing machines. Capacity for future expansion is currently still unused, a clear signal for planned growth.

A special feature of Elasto is the very wide range of colors that the company offers. “Batch sizes from 5000 units upwards are available in any color,” says Sperber. Materials are assigned using barcode labels and hand scanners. The central M8 control system automatically checks whether the combination of material and machine is correct before the transfer starts. This eliminates sources of error that could previously occur in the decentralized system. “The M8 control system was accepted very well by the whole team,” says Rösel. “Following training at Wittmann, they could all work with it without any problems. Although the RFID-controlled granulate supply was a complete novelty for everyone.”

Challenges mastered during the move

Due to its proximity to the Wittmann branch in Nuremberg, Elasto was able to implement the system change with close support. “Whenever we cannot help online, we will come very quickly in person,” emphasizes Wolfgang Prütting, Area Sales Manager at the Wittmann Group. A previous visit to a reference customer played an important role in the decision in favor of Wittmann: “We visited a major manufacturer of electronic components to see how they work with Wittmann's system. We spoke with staff members on site and saw that their response was very positive,” reports Rösel. The implementation went quickly: within two weeks, the injection molding shop was relocated and the new material supply system was put into operation without any lasting interruption to the production flow.

New material flow improves process quality and recyclate use at Elasto

The new material flow has led to significant improvements in production. Color changes can be carried out much more quickly, and unused granulate is automatically collected via a return system. This has significantly improved occupational safety, consistency, and material utilization. “The central material supply system has substantially improved our processes,” concludes Markus Rösel.

One reason for this is the use of Feedmax Clean conveyors with integrated dust removal. “The Feedmax Clean reaches extremely high extraction rates of up to 80 per cent of all particles below one millimeter in diameter,” explains Prütting. This system was developed by Wittmann to meet the increasing demands of the circular economy and to make recycled materials usable even for demanding applications.

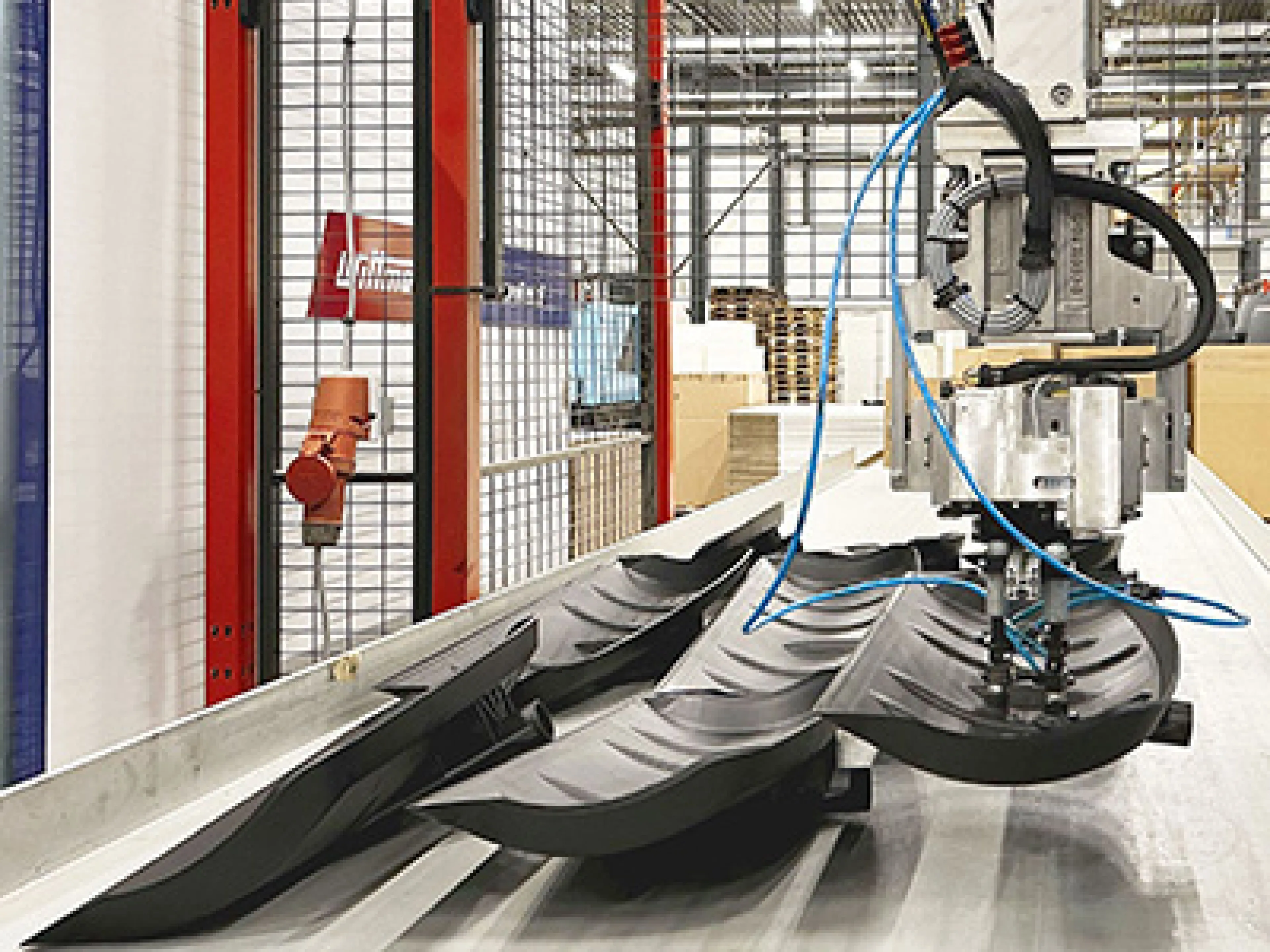

Rösel adds: “For products not certified for direct contact with food, we use regrind more and more often.” One example from the portfolio is the “Profi 320” tray made of recycled polystyrene, which is manufactured using two-component injection molding with in-mold labeling (IML).

Sustainability as part of the growth strategy

Elasto is the first company in the promotional products market to be ISCC Plus certified, which confirms its use of resource-saving raw materials. In addition to recycled materials, polypropylene from forestry and agricultural waste also contributes to the certification. The photovoltaic system on the new logistics center, with 1,560 solar modules, provides enough energy on sunny days to completely power production: “On a sunny day, we can operate entirely with energy produced in-house”, emphasizes Sperber.

Elasto automates logistics and reduces CO2 emissions

The new logistics hall offers 5,500 square meters of space, including space for 5,000 pallets and a small parts warehouse with 7,000 KLTs. Products in high demand are stored there. Automated processes bring items to the employee in shipping, who then performs the final finishing steps such as engraving or packaging. “We can only handle such small individual orders efficiently, because we have optimized and automated our processes also in the logistics department,” emphasizes Sperber.

20 percent increase in efficiency in Elasto granulate supply

Overall, production flexibility at the headquarters has increased significantly. This is a decisive advantage in international competition. In conclusion, Rösel assesses the impact of centralised supply as follows: “But we have certainly become about 20 per cent more efficient in granulate feeding.” And Sperber sums up the strategic benefits: “The central material supply system definitely helps us to produce competitively. We now have the necessary efficiency to make products in Germany, which others buy from Asia.“