Emballator and Henkel Adhesive have been working together for more than three decades to develop safe packaging solutions for demanding industries such as the chemical industry. Metal buckets, cans, and lids used in this industry must meet the highest requirements for leak tightness, durability, and safety. A recent milestone in this partnership is the introduction of phthalate-free sealants. This...

The food industry is under pressure: rising labor costs, higher sustainability targets, and the need for more efficient processes. Middleby Food Processing has teamed up with Rockwell Automation to develop the first fully automated bacon production line. The solution reduces labor and water consumption, increases throughput, and sets new standards in the industry. This article shows the...

The Damm Brewery in Barcelona has a history spanning almost 150 years. Today, it is the second largest brewery in Spain, with much of its production exported to Portugal and England. In the spacious and modern brewery, most of the beer is bottled in cans of all types. To ensure that these are undamaged, contain no foreign objects, that the contents match the label and that the best-before date is...

Asahi Kasei is supplying a one-megawatt alkaline water electrolyzer to the Central Finland Mobility Foundation (Cefmof). The compact, container-sized "Aqualyzer C3" system is scheduled to contribute to hydrogen production in Jyväskylä from 2026 and will be a key element in the decarbonization of the Central Finland region. The decision to use this water electrolyzer is based on the manufacturer's...

Mondi has introduced a digital printing solution that allows Komsa, a leading German distributor for digital infrastructure, to dispatch up to 35,000 parcels per day without using adhesive labels. The printed barcodes on corrugated packaging reduce material usage and streamline logistics processes. Using Mondi’s advanced digital printing technology, consecutive barcodes are printed directly onto...

The French Eram Group is relying on Dematic technology for its new logistics center. An "AutoStore" system featuring 84 robots and integrated control software is designed to centralize and automate processes. The group, known for brands such as Gémo, Eram, Bocage, and Mellow Yellow, is consolidating its logistics operations at a new distribution center located in Chemillé-en-Anjou, western France...

With support from Siemens, Sachsenmilch Leppersdorf has implemented a future-oriented maintenance strategy. The solution used is Senseye Predictive Maintenance, which is based on artificial intelligence and continuously monitors the condition of technical equipment. This enables the milk processing plants to avoid production downtime and manage maintenance in a targeted manner. This is a decisive...

The supplier Osbra, based in Bad Wörishofen, Germany, is a sought-after partner for numerous premium automotive brands such as Mercedes-AMG, Porsche, BMW Alpina, Aston Martin, and Maybach. Deciding whether it is worth investing in injection molding tools or whether the higher unit price for processing polyurethane (PUR) is economically viable is part of everyday business at Osbra. The quantities...

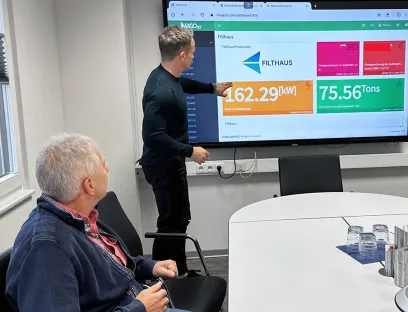

Energy efficiency in plastics processing is not just a sustainability issue, it is crucial for competitiveness. Data-based systems for analysis and optimization are becoming increasingly important, especially in the packaging sector, where unit costs must be calculated precisely. The injection molding company Filthaus in Meinerzhagen uses the “iMAGOxt” energy monitoring system from Wittmann to...

Transparency is an essential part of Bell's corporate philosophy. This does not primarily refer to transparent plastic materials in production. Rather, Bell is committed to transparent communication with end users. This is because the Polish cosmetics manufacturer is focused on sustainability. Only equipment and systems that are very energy-efficient, such as Wittmann injection molding machines...