From September 23 to 25, 2025, the Kahl Group, together with Amandus Kahl, Schule Mühlenbau, and Neuhaus Neotec, will be presenting its wide range of solutions for processing powders, liquids, and bulk solids at Powtech in Nuremberg. In addition to food and chemical applications, the focus this time will be on pharmaceutical applications. Amandus Kahl will be highlighting two key processes: pelletizing and fluid bed technology.

Pelletizing and fluid bed technology

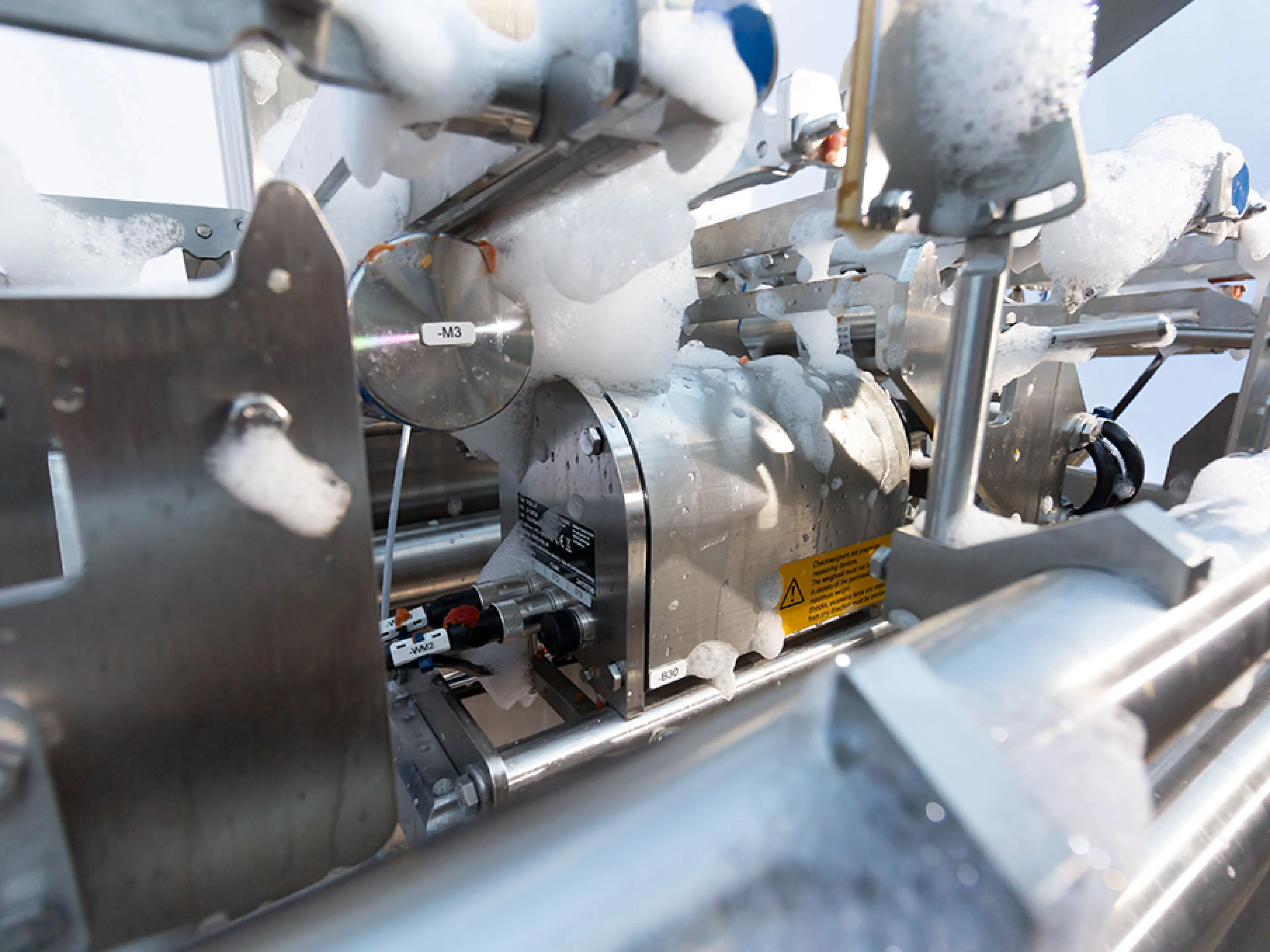

The “LFB mini S” fluid bed system and two flat die presses will be on display. Of particular interest to the pharmaceutical industry: the compact “14-175” press and the powerful “33-600” press can be optionally certified according to GMP guidelines. This means they meet the requirements of “Good Manufacturing Practice” and ensure the safe, reproducible manufacture of pharmaceuticals.

Laboratory and production solutions with GMP option

The systems are suitable for use in laboratory environments as well as for industrial production. GMP certification enables pharmaceutical manufacturers to ensure that their processes meet regulatory standards. This allows granulated and pelletized products to be manufactured in high quality and under hygienic conditions.

Complementary technologies from the Kahl Group

While Amandus Kahl showcases its pharmaceutical-oriented process engineering solutions, Schule Mühlenbau expands its portfolio with a centrifugal peeler for grain processing. Neuhaus Neotec, previously strongly represented in the coffee industry, is also positioning itself with two-stage laboratory mills and large-scale roller mills for chemical applications that require precise particle size distributions.

Common goal: efficiency and quality

All three companies in the Kahl Group pursue the goal of enabling economical and sustainable production processes through precise process engineering. For the pharmaceutical industry, this means that manufacturing processes and their sub-aspects, such as pelletizing and fluid bed technology, can be made more efficient, safer, and compliant with regulations. You will find the Kahl Group at Powtech 2025 in Nuremberg in Hall 12.0 at Stand 12-487.